Results 1 to 6 of 6

-

06-22-2015, 11:51 AM #1Student

- Join Date

- May 2015

- Posts

- 49

What is my nozzle size and type of extruder?

First, I'm trying to figure out what kind of extruder I have and what my nozzle size is. I bought the printer from the 2nd owner - he doesn't know.

If I let some filament ooze out of the extruder and measure it, I'm getting 0.5mm. I've done that several times with short strands and long strands, pretty much 0.5 mm. Is that really the nozzle size, or since it's not really being extruded under pressure, is the nozzle smaller?

I also don't know what kind of extruder I have:

Is this the type of extruder where I can change out the nozzle? If so, where's a good place to look for other sizes (like may 0.3mm)?

Thanks,

-

06-22-2015, 12:37 PM #2Banned

- Join Date

- Jan 2015

- Posts

- 306

Best way to know what orifice size you have is to get different diameter guitar wire and keep inserting them until the one that just barely fits, goes in with a little bit of force. That is your diameter. Also, it looks like you have PEEK hot end, not sure who makes that but it doesnt look like an all metal hotend. You are temperature limited to about 245C.

-

06-22-2015, 04:21 PM #3Student

- Join Date

- May 2015

- Posts

- 49

Great idea. I don't have guitar wire, but how about solid copper wire? I guess it would be soft enough not to damage the orifice.

You are correct, I do not believe the barrel is metal. I have Slicer set to print at 205C, but based on your comment I'll change the printer setup to max out at 245C just as a safety.

-

06-22-2015, 04:30 PM #4

I don't have one, but to me the hot end looks like a Jhead, which has a body formed from PEEK as DBFIU mentions. They also have a PTFE liner tube. Browsing a bit, I see more than one approach to the jhead. Some have a removable nozzle, some have a nozzle that is machined out of the same brass block as the heater block. If the nozzle part doesn't have a hex pattern to it that could be grabbed with a wrench, you have the single machined block type.

-

06-22-2015, 10:02 PM #5My bet is it is a .4mm nozzle. It is going to oooze thicker than what the hole is. If you assume (and setup your Slic3r) for a .4 mm nozzle, it won't be hard to see if that is right.If I let some filament ooze out of the extruder and measure it, I'm getting 0.5mm. I've done that several times with short strands and long strands, pretty much 0.5 mm.

-

06-26-2015, 04:07 PM #6Student

- Join Date

- May 2015

- Posts

- 49

I tried using small single-strand wire to get an idea of the size of the orifice. Looks like .45mm. Hard to be sure because wire sizes aren't very accommodating for .3, .4, etc. mm sizes.

I'd like to change to a .3mm nozzle. The existing nozzle looks like it was machined out of one block, so not interchangeable.

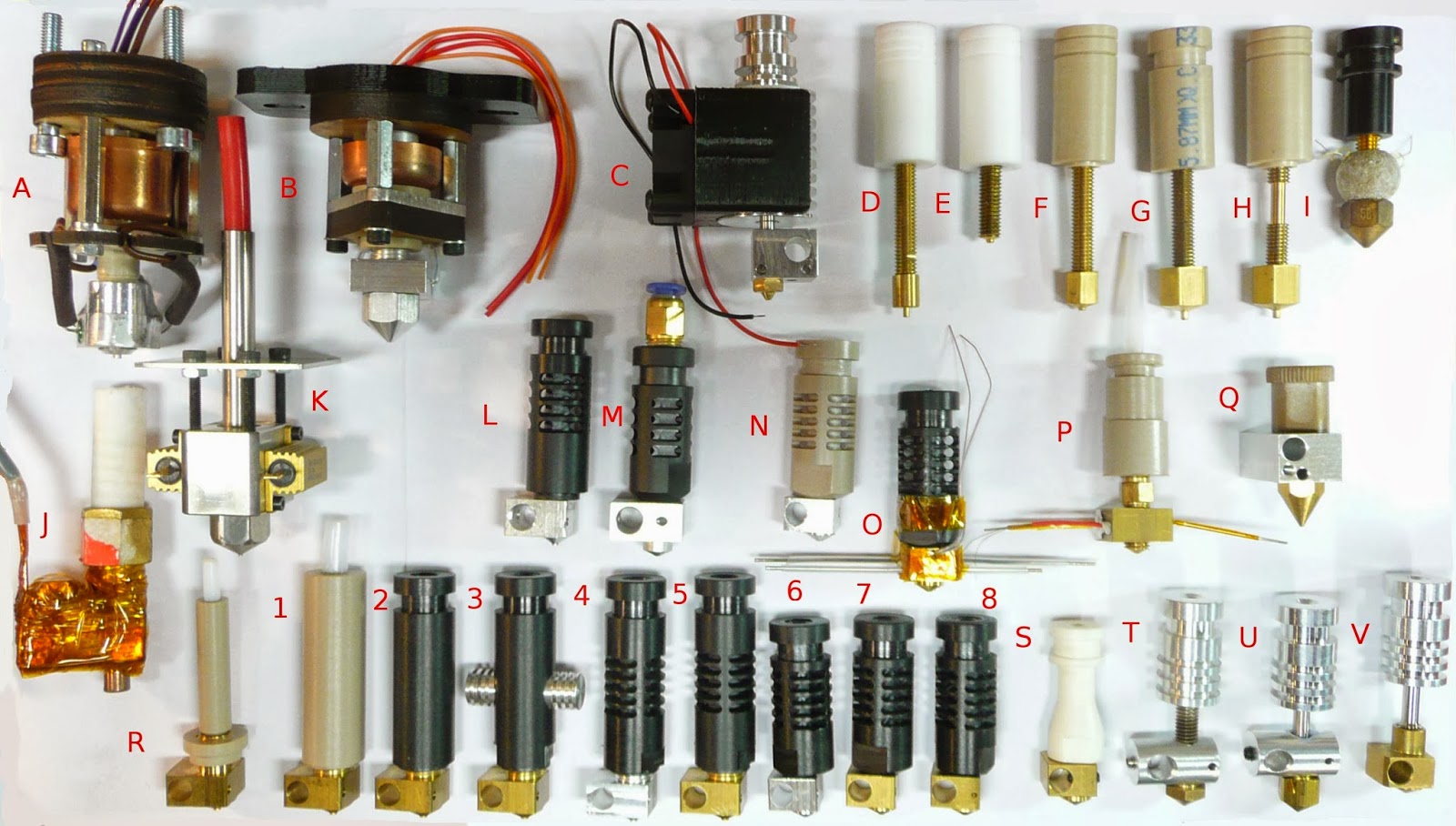

Now that you pointed me in the right direction, I found and the hot end/nozzle looks like #5, #7 or #8. So I'd like to change out the hot end for .3mm. It looks like just above the hot end there are two screws in the bottom of the extruder. If I loosen them, is it probable that the hot end will come out and I can replace it? I have not problem with the wiring aspect of the change-over, but is the mechanical aspect as simple as loosening the screws, pulling out the old hot end and inserting the new one? Or is there some alignment that needs to be done so it feed properly (if feeds fine now).

and the hot end/nozzle looks like #5, #7 or #8. So I'd like to change out the hot end for .3mm. It looks like just above the hot end there are two screws in the bottom of the extruder. If I loosen them, is it probable that the hot end will come out and I can replace it? I have not problem with the wiring aspect of the change-over, but is the mechanical aspect as simple as loosening the screws, pulling out the old hot end and inserting the new one? Or is there some alignment that needs to be done so it feed properly (if feeds fine now).

Also, given this type of hot end, any recommendations for a decent replacement?

Thanks for all of the help.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Today, 04:18 AM in Tips, Tricks and Tech Help