Results 1 to 10 of 11

-

05-12-2015, 06:44 PM #1Technician

- Join Date

- Mar 2015

- Location

- Fenton, MI

- Posts

- 63

Can you help me figure out what went wrong?

I took a few weeks off from hobbies and such due to family circumstances and am printing again. I only mention this because I want to help others as much as I'm being helped. Anyway, I did my longest print yesterday, 12 hours. And had a failure I was hoping you good folks here could help me to understand.

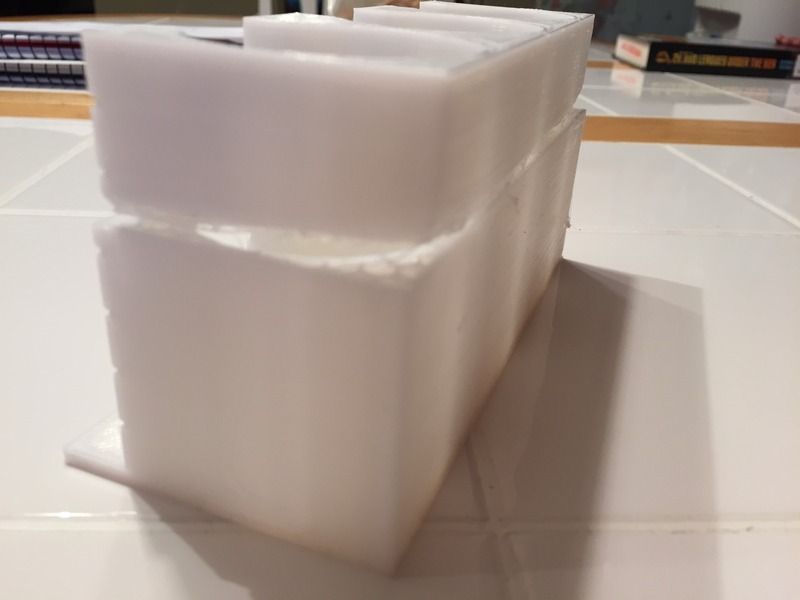

The part is something I designed in sketchup, pretty basic and simple. All was going well for most of the print. But I woke up this morning to this

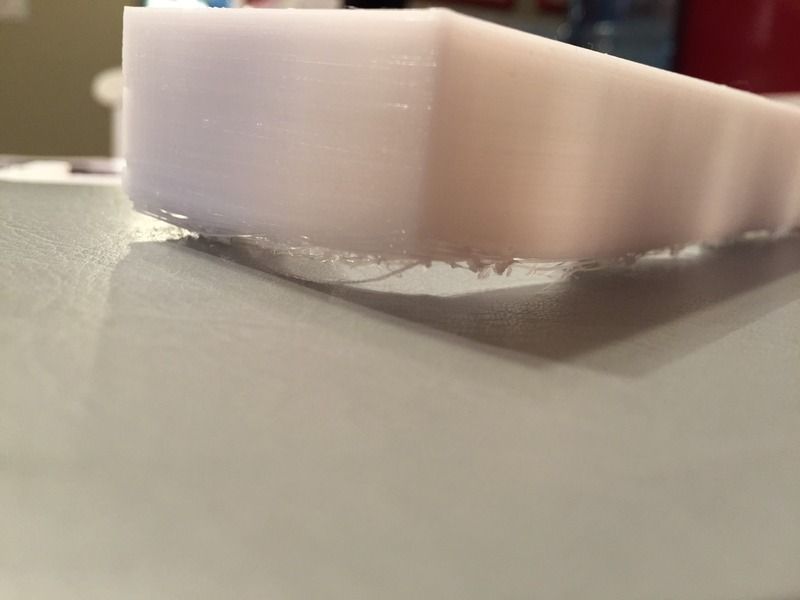

The lower 3/4 of the print. It seemed to have printed very well, clean lines, good quality. Then, at about the 3/4 mark there are odd paths that look like it wasn't going around the circle, and all sorts of odd behavior. Here's more pictures.

This was printed on a Prusa iV3 10" and sliced with slic3r using PLA. I am not home right now so I don't have all the slicer settings, but I know it was .2 layer height, 195 nozzle temp and 65 bed temp.

Anything else you need to know? If you want to see the sketchup, stl, or g-code files, how to I attach them?

What seems especially odd is that the print is very good, except for that one small segment. The corners kinda curled up at the end. Those stray threads that I initially thought were odd motion paths, I now suspect that the issue was that the filament didn't stick the whole way around the circle, but stuck at point A and B, making the straight line.

-

05-12-2015, 11:17 PM #2Engineer

- Join Date

- Aug 2014

- Location

- Montreal, Quebec

- Posts

- 576

Ah typical underextrusion, could be a temperature control failure or something else that just jam your extruder for an instance.

-

05-13-2015, 12:53 AM #3

-

05-13-2015, 01:39 AM #4Senior Engineer

- Join Date

- Jun 2014

- Location

- Burnley, UK

- Posts

- 1,662

Maybe the table dropped. How does the height compare to what it should be?

-

05-13-2015, 02:03 AM #5Engineer

- Join Date

- Aug 2014

- Location

- Montreal, Quebec

- Posts

- 576

-

05-13-2015, 02:13 AM #6

I'll just blurt out what came to me :

- Did your spool get tangled and snagged temporarily ?

- Do you have filament shavings on your extruder gear ?

- it looks like your xy plane shifted at that spot, is that correct ? That could be belt tension.

-

05-13-2015, 11:20 AM #7Technician

- Join Date

- Mar 2015

- Location

- Fenton, MI

- Posts

- 63

The issue happened over-night, so I don't know if anything got snagged. I don't see any shavings in the extruder at all. And I think the X/Y shift-look is because the picture you see is after I removed the part(s) and put them on my table. When I walked up to the printer I didn't even notice the issue. When I grabbed it I noticed that the top wasn't even really part of the bottom. Only spider webs holding them together.

What could cause under extrusion like that, besides an obvious jam in the extruder? What's really odd to me is that it resumed printing, and did a dang good job. I'm hesitant to try it again, that was quite a bit of plastic and time.

-

05-13-2015, 02:05 PM #8

It doesn't look like that much plastic. I would print it again when I could keep an eye on it. If the print fails again, at least you will be able to see what is happening and have a good clue what to do to fix it.

-

05-13-2015, 02:52 PM #9Technician

- Join Date

- Mar 2015

- Location

- Fenton, MI

- Posts

- 63

I'll have to ask around and see what print speeds folks are running these Prusa iV3s at. This was a 12-hour print, it seems I'm hardly at home for 12 hours at a stretch where I'm not sleeping haha.

-

05-18-2015, 12:25 AM #10Student

- Join Date

- Feb 2015

- Posts

- 29

The strings are probably caused by inappropriate values for extruder retract and prime values. Correct values vary by printer, extruder, and from what I can tell, slicer softwarealso. i'm currently at 5.5 mm for each. You'll have to do a bit of experimenting to determine what works best for your situation.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Today, 04:18 AM in Tips, Tricks and Tech Help