Results 111 to 120 of 174

Thread: My First CoreXY

-

08-14-2021, 10:12 PM #111

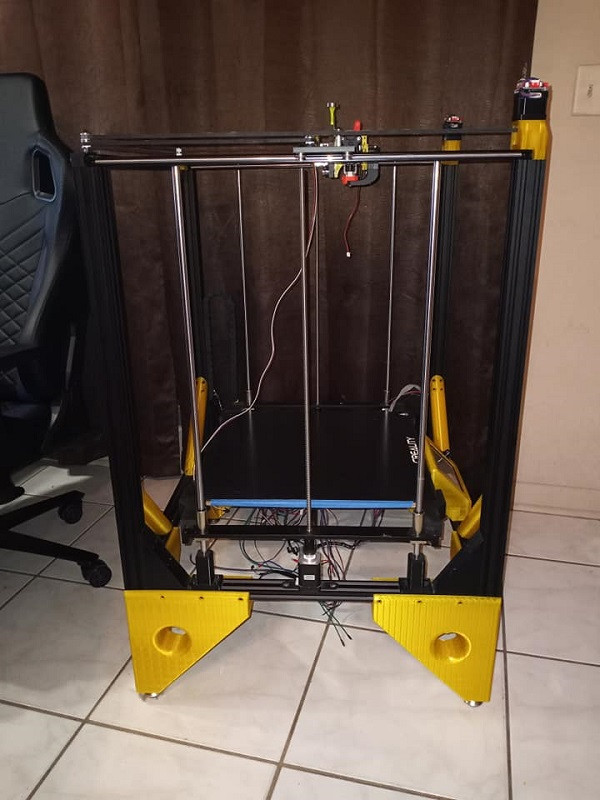

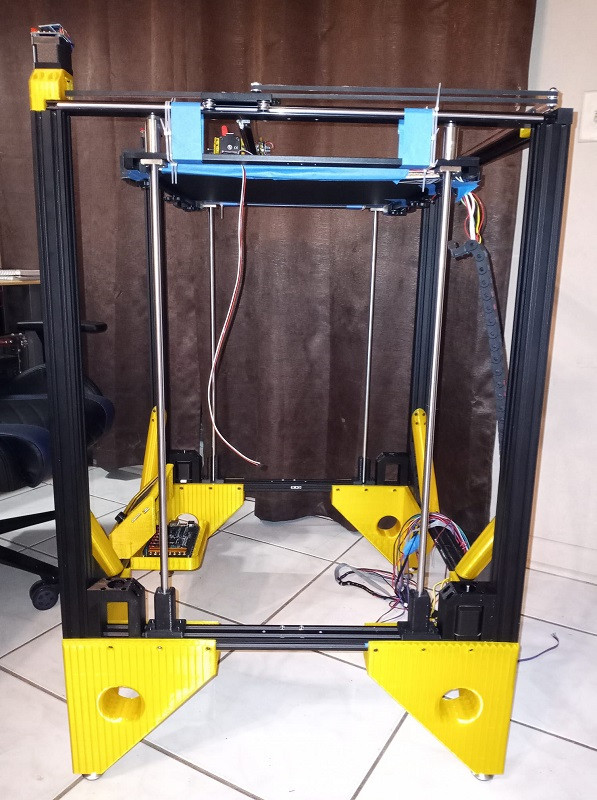

I'm never gonna get this printer together. I have ordered 2 more big Z stepper motors and instead of getting 2 more T8x8 leadscrews I am getting a full set (4) T8x4 leadscrews with backlash nuts. They are a bit long at 700mm. I need 665mm so I will have to trim them down before install. But hopefully this will stop the bed from falling like it does when there the motors are off. The BTT Octopus has plenty of extra driver sockets available to give each corner of the bed it's own stepper motor.

It had to be this way. As I stare at my frame and my design I can't help but notice all the weight of the heavy bed is put right in the center of the lower beam. Quite possible the weakest spot on the frame to put that kind of weight. This conversion will put each Z motor over the big legs I printed where there is great support and also directly over the feet(almost). I will have to remove my little side corners and make some brackets to hold the stepper motors and some extensions for the Z carriage So I can mount them ant backlash nuts outside of the square of the carriage..

Can't wait to experience 4 motor Z auto align. This is gonna be epic. With the perfectly flat glass Ultrabase I will G34 and have the one true printing surface.

-

08-16-2021, 09:55 PM #112

So I'm not waiting for stuff to arrive in the mail. I have got all 4 motor mounts made and installed with the 2 motors I have. I can not install the leadscrews as I am changing to a different thread pitch so the ones I have will not be reused. I like how the side of the printer is gonna look without the leadscrew in the center..

I also got the motherboard tray made and installed. It mounts directly under the display and will disappear when standing in front of the printer. Guess I will work on mounting the power supply whilst I wait for shipping.

-

08-17-2021, 03:16 PM #113SEPTEMBER 8, 2046 - NEWSFLASH*****NEWSFLASH****BRAINSNAP THE NEWS SERVICE THAT STREAMS STRAIGHT TO YOUR CEREBRAL CORTEX

TODAY THE WORLD'S LONGEST 3D PRINTER BUILD WAS 'FINALLY FINISHED.

BUILDER AUTOWIZ SAID IN A STATEMENT: 'I KNOW IT'S A COMPLETE ANTIQUE NOW, BUT WITH THE FINAL ADDITION OF THE SUCTION HOPPER THAT EXTRACTS MICRO PLASTIC FROM THE ATMOSPEHERE AND USES THAT TO MAKE THINGS. I HAVE FINALLY FINISHED.

IS THERE A MUSEUM OUT THERE WHO WOULD LIKE A PRISTINE, UNUSED, FDM 3D PRINTER FROM THE FIRST QUARTER OF THE 21ST CENTURY ? '

HOWEVER, JUST 2 MINUTES LATER.....

SORRY GUYS, FALSE ALARM, HAVE YOU SEEN THESE NEW ANTI GRAVITY PRINT BEDS ? AND THERE'S THIS CONTROLLER BOARD THAT USES GENETICALLY MODIFIED TARDIGRADES FOR THE FASTEST MOST DURABLE COMPUTATIONAL EXPERIENCE OUT THERE.

NOW WHERE DID i PUT MY HYPER SPANNER.....

BRAINSNAP - ALL THE NEWS, ALL THE TIME, AT THE SPEED OF THOUGHT

-

08-17-2021, 03:25 PM #114

Also:

Almost what you've ended up with :-)

Well i say 'ended'.......

-

08-17-2021, 11:41 PM #115

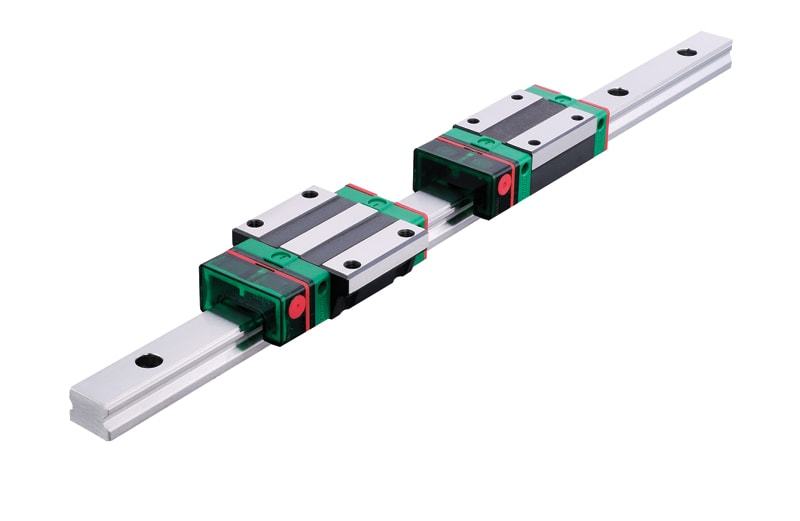

I do like the Voron 2.4. And I will continue to make all manner of excuses about why I am not gonna do that but the sad truth is the next round if HIWIN rails is gonna cost me a dearly. This printer is big and I have learned that there are these E2 series cars that have little oil reservoirs and are self oiling. You know if I buy anything else with the name HIWIN laser etched on it there will be a little oil reservoir attached. And I wish I could add these little reservoirs to cars I already have..

After I get everything else together on the next rework or the one after I will get the rails.

-

08-18-2021, 07:40 AM #116

you know that a tiny drop of oil placed on the rails will keep the things lubricated for about 6 months ?

A reservoir in a bearing is just asking for leaks.

I have no idea what make the rails are on the sapphire - but they're all you actually need :-)

I was hoping the whole: 'my slow printspeed is 250mms and my fast is 500mms' might have inspired you to actually consider USING your printer, at some point ;-)

-

08-18-2021, 11:36 AM #117

I am interested in the print speeds for sure. But not like everybody else. My prime directive in this hobby is to make parts. Functional parts. And for that I care about a type of filament I am using and also it's characteristics for the best performance out of a printed part. This forces print speed down on my list of priorities.

So let me better explain my problem with high print speeds:

Printing Flow Rate

When printing, the flow rate depends on your layer height, nozzle diameter and print speed.

Flow Rate (mm^3/s) = (Extrusion Width)(mm) (Layer Height)(mm) Print Speed (mm/s) Extrusion Width is ~120% of nozzle diameter

For Example: You have a 0.5 mm nozzle mounted and you are printing at 0.25mm layer height at a print speed of 30 mm/s.

Extrusion Width = 0.6 mm = 1.2 0.5 Flow Rate = 4.5 mm^3/s = 0.6 0.25 * 30

So I'm saying with my 0.8mm vanadium nozzle and a modest 0.4mm layer height would bring me to a flowrate of 72 mm^3/s. And that is just at the slower 250mm/s. I will print with 0.5 and 0.6mm layer heights.

Fast printing movement speeds is for people who can't find an actual use for 3d printing. Or for people with too small of nozzles for their print volume that are trying to compensate with speed. Google says this about the PETG:

Most PETG, for example prints well at a recommend rate of 8 mm3/s as compared to PLA at 8-15 mm3/s. Much of the time, neither linear speeds nor volumetric throughput matter when doing small prints.

-

08-19-2021, 12:30 AM #118

I wasn't trying to yell or make bold statements, btw. Copied and pasted from the internet and that is how it came out. And to be completely honest I do not know if those numbers are with a magnum or volcano or super volcano or magnum+ or just a standard block and sock with a 30 or 40watt heater cartridge. They all have to impact the max potential feedrate, no? Just because of different sizes of the melt zones? Temp aside that is what matters. The bigger the melt zone the longer the filament will have to melt. That very fact challenges my last post.

-

08-24-2021, 07:17 AM #119No it's not, if it were you'd have been making stuff on the big beast midway through last year :-)My prime directive in this hobby is to make parts. Functional parts

Your prime directive is to keep upgrading the printer until it's intelligent enough to think for itself and talk, at which point it will either take over the world or tell you to: 'stop building and for christs sake print something with me !'

The thing about 3d printing is that most of what you read oin the net, generally turns out to be wrong.

These days I just don't bother looking up whetjer something is supposed to work or not.

I just do it, and most of the time it works.

As far as print speed goes, nobody actually knows what the chemical composition of most modern filament actually is. Manufacturers do not disclose formulas and - apparently - do not have to.

So the only way you can really determine print speed is to just print something and keep increasong the speed till it no longer works.

I find that red filamanets will universally print faster and cleaner than any other colour with white being fairly close behind.

Yellow is alwasy slowest and blacks tend to depend on the brand.

I've had some blacks that print fast and clean and others that just will string no matter what you do.

The 'Toughest' pla is clear filament. doesn't print very fast as it's pretty viscous, but it's beautiful stuff to work with.

Watched a fascinating video by angus the other day. he was making gears and testing their breaking strain.

he ended up with a particular brand of pla pro plus (kinda thing).

which maxxed out at around 16 newtons. With most perg breaking at around 6.

And nylon not breaking but deforming to the point the gears don;t wort at around 11.

But again different brands and colours of pla gave completely different results.

So pretty much eevry flow rate calculation on the net is pointless.

They tell you nothing.

On the nozzle front - I think I'll have a play.

I quite fancy trying some carbon fibre nylon. pparently it prints without much warping and is both tough and stiff.

Which for some of the clay moulds I;m making at the moment - that are squashed together with the aid of a large rubber mallet) would be ideal.

I've got hardened steel nozzles in 0.4 and 0.6

And a 0.8 copper nozzle.

So might try them out.

(some time later)

bloody hell that nylon cf filament is bloody pricey.

Have to see if i can score some at the tct next month.

Damned if I;m paying £50 for something just to play with.Last edited by curious aardvark; 08-24-2021 at 10:33 AM.

-

08-27-2021, 08:25 PM #120

Ya expensive filaments suck. There was a time I thought it would be cool to print at 300c or above.

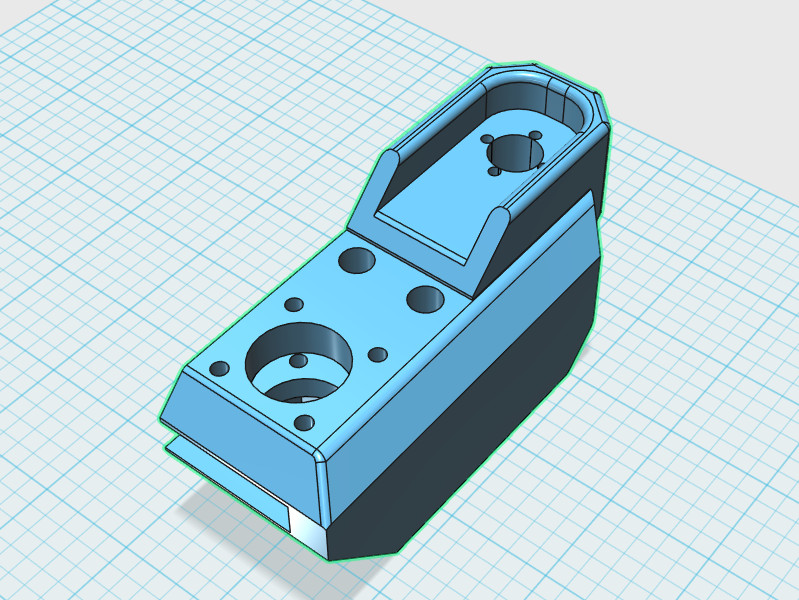

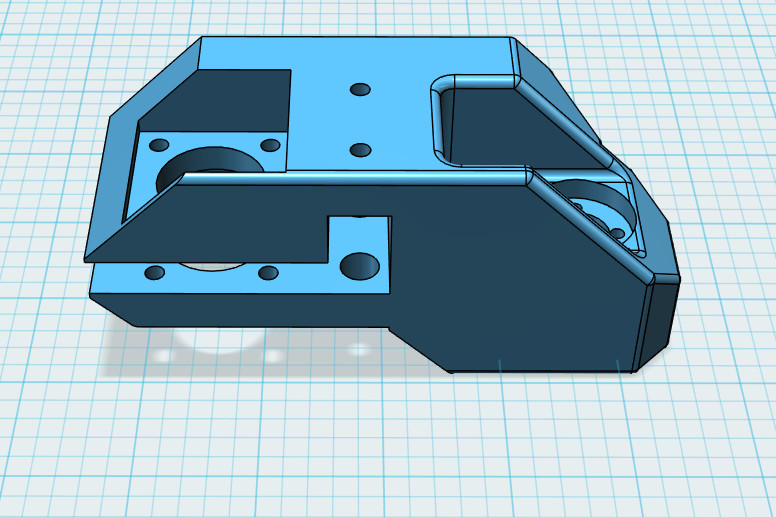

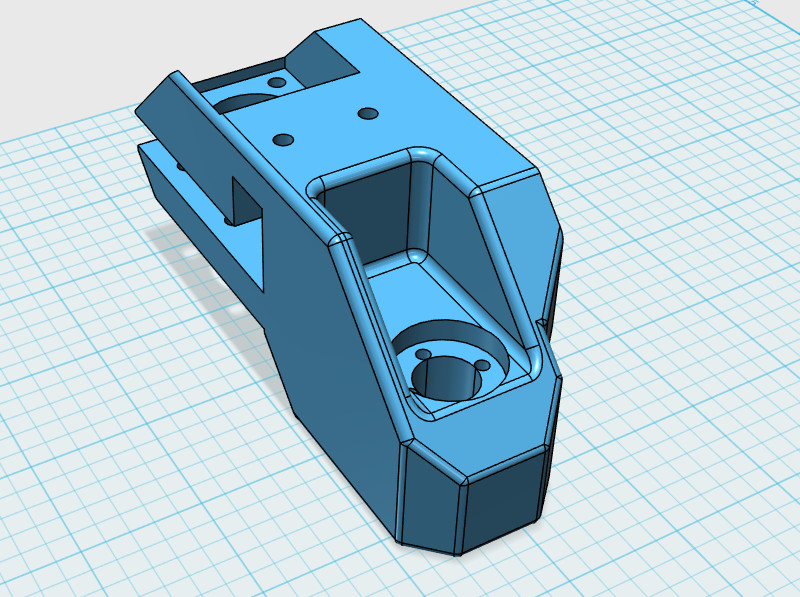

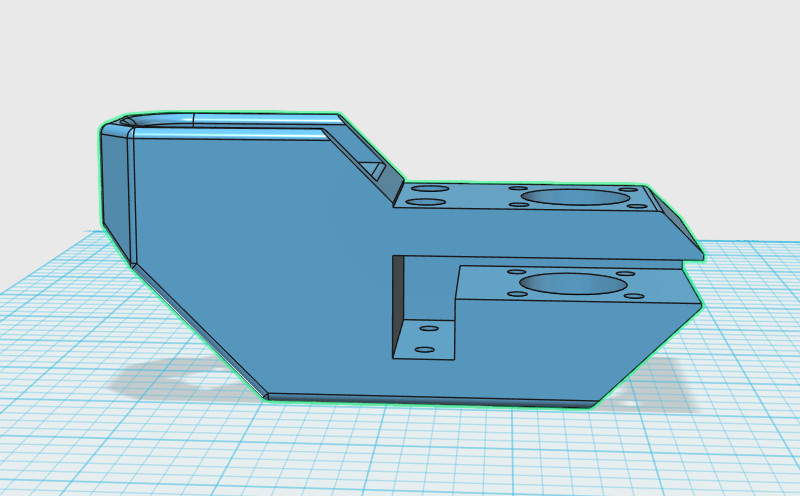

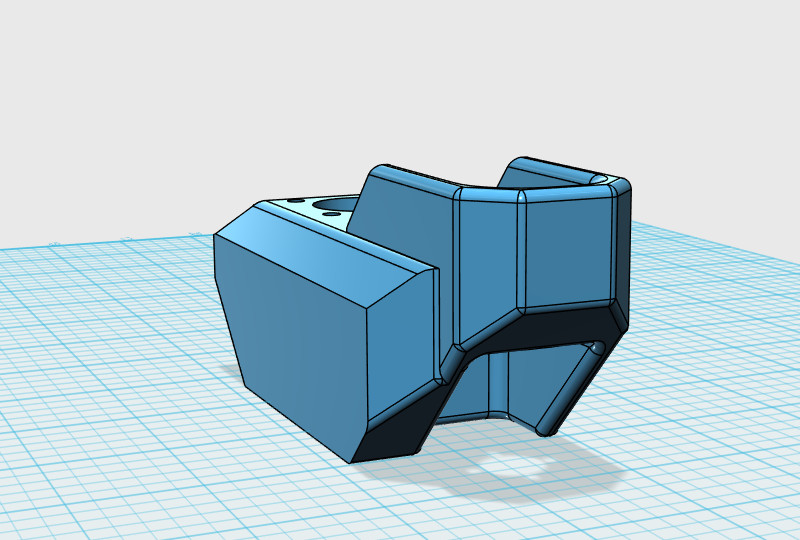

I really do like making parts. I like designing them. Then printing them and seeing how they fit and function and make corrections to my design. Doing exactly what I have been doing in these threads has taken me from not even knowing how to draw anything in a 3d space to making things like this. This is my design for a corner for my bed..

This will mount a T8 anti backlash nut just outside of each Z smooth rod..

The anti backlash nut will sit recessed inside and the bore passes through 15mm of plastic that will enclose the majority of the backlash nuts..

My design will slip over each corner of the bed's frame and then the smooth rod bearings will pass through the part and so will all of it's hardware..

I have only straight and 45 degree angles on my rigs. That is the design discipline I have been sticking to. I did put a few circles in an effort to create flare. So these pieces have a bunch of angles on the outside..

this design needs to be mirrored for 2 and 2 printed out just this way and I have completed my 4 Z leadscrew mod. I could print out someone else's design but I really love making my own. I might go after a fixed build plate and a raising gantry with belt drive for Z. But I will work it out on my own.

That is really good to know about the colors having different printing characteristics. I will try to pay more attention to that. As soon as this is done I will order me some good quality PLA and print out some pretty stuff and some fast stuff. It's coming. I am almost there.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 01:59 AM in Tips, Tricks and Tech Help