Results 1 to 10 of 27

-

08-18-2020, 11:13 PM #1

I Need Help With Multi Material Printing

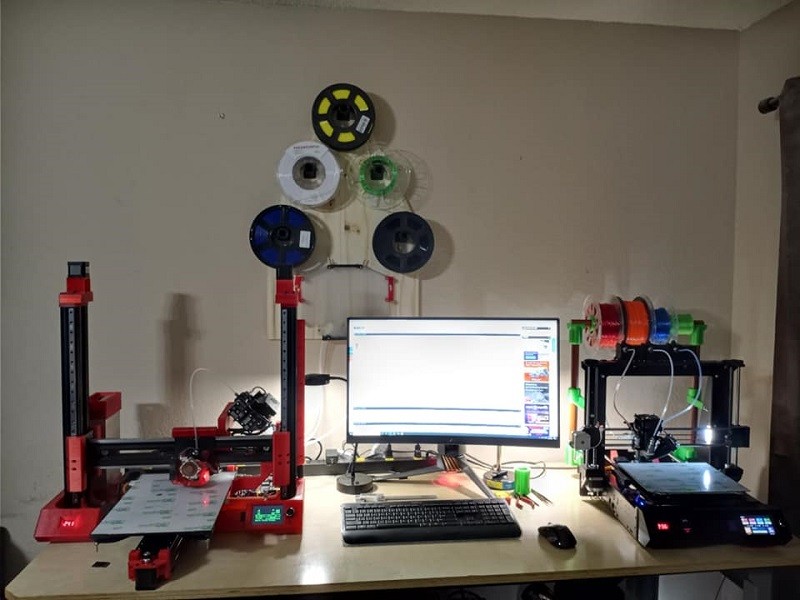

I have finished building my 2 multi material rigs. One with a MMU2S and one with a Diamond Hot end. I have both printers working. The red printer with the MMU2S I have had printing without the MMU2S connected and calibrated it pretty well before connecting the MMU2S and adjusting the settings in marlin 2.0.5.3 for it. The black printer with the diamond hotend I have printing with whatever first color I use. I am all setup and ready to figure this out. Here is my current workbench configuration..

-

08-18-2020, 11:39 PM #2

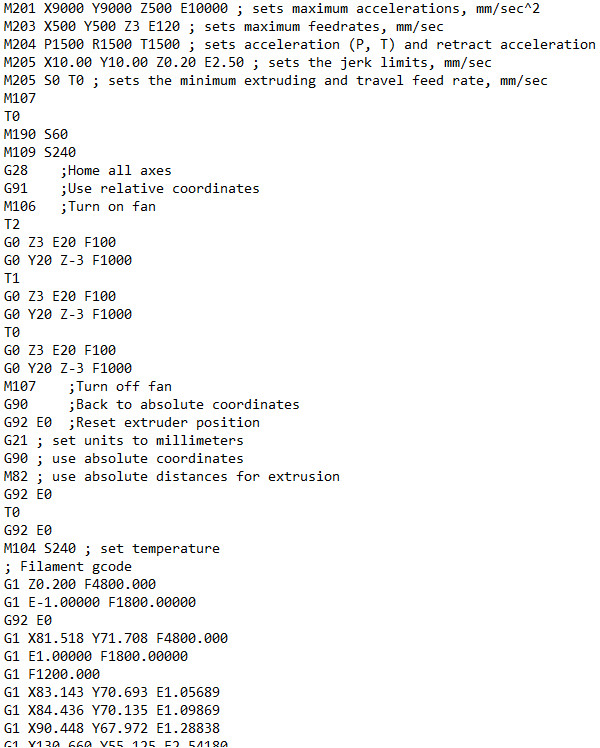

I have heaters pid autotuned, end stops calibrated, printer configurations all setup in both S3D and PrusaSlicer although I am pretty sure I am missing from the start gcode on both. I have built and wired these machines well. I know the right youtube tutorials to follow now to tune for speed and salmon skin and other quality issues. If I can just get past these few issues with either the slicer or marlin I know these machines will impress. I am pretty sure I am closer on the diamond hotend. Currently it will start a print with the first nozzle but when it switches to the second filament the printer just freezes. I have to cycle the power or push the reset button. This printer has marlin 2.0.5.3 and I have enabled 3 extruders and single nozzle and everything has compiled and with PrusaSlicer I have 3 extruders set and even set the correct color to each filament in the slicer. I found some start Gcode that included leaving a blob of each color filament as a prime just before the print starts. When i apply this Gcode to Prusa slicer it behaves correctly and I get 3 blobs. There was no purging action so the blobs aren't exactly all the right color but there is no mistaking that all 3 extruders function correctly here. Just when I start printing that multi colored gecko after the first color, at the moment it is supposed to start using the second extruder the printer just freezes. I have tried re loading and reslicing the file and any settings that i am playing with aren't getting me any results. Anybody out there have any ideas what might be my problem with the Diamond hotend rig?

-

08-19-2020, 03:29 AM #3Technologist

- Join Date

- Oct 2016

- Posts

- 184

Couple of things I check:

- open the gcode file and see if there's commands that don't belong there. A pause maybe (M600) or emergency stop (M112) or something else...

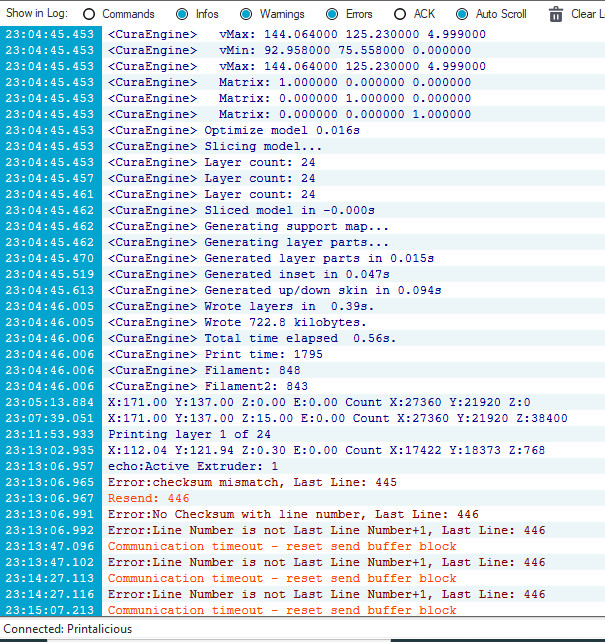

- connect to the printer usb and see if there's errors printed. Also at least in Octoprint, the commands sent to the printer can be seen in the console log so that helps tracking down the problem

-

08-21-2020, 08:05 PM #4

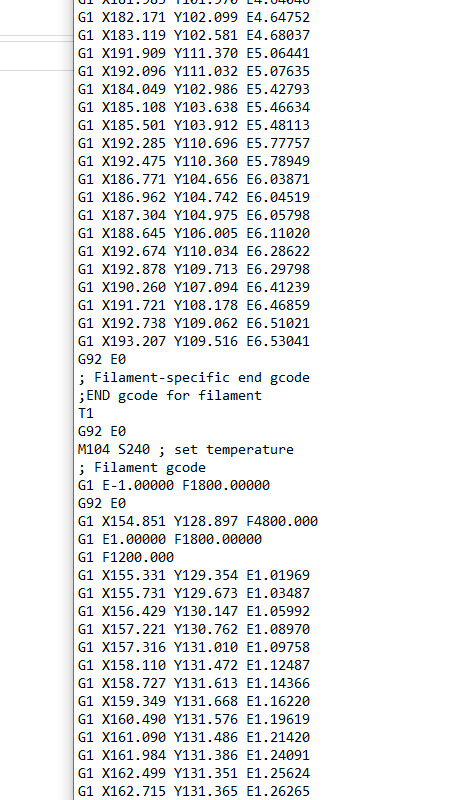

You know I have never actually opened a sliced file to look at the gcode before. Terrible ain't it? Well I looked at a few different single filament gcode files as well and it is not hard to understand at all. But i do not understand what switching to another extruder should look like. This is the diamond hotend. It needs no retraction or anything just to start using a different stepper for E. I opened the sliced 3 color lizzard and scrolled down to where the first 'toolchange' should happen and i believe this is the exact point my machine chokes. But i do not know if it is good or what using e1 now instead of e0 would look like as gcode. Here is where the gcode changes filaments for the first time and where my machine hangs not like the print stopped but I have to cycle power to regain control of the printer. It freezes.

-

08-21-2020, 08:22 PM #5

-

08-21-2020, 10:21 PM #6

-

08-21-2020, 10:38 PM #7

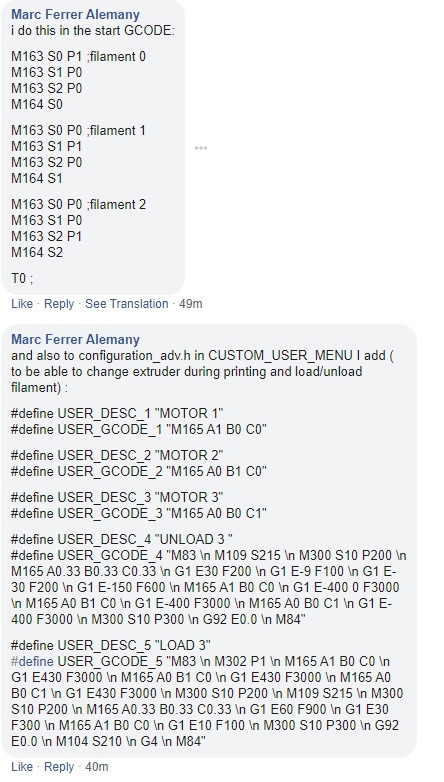

I also posted up these screenshots with a quick description of my problem in the 3d printing multimaterial facebook group and someone posted this up. Spegelius does this make sense to you? I think i know where he is saying to put it but i do not understand a lick of it. Is this right or gonna hurt me?

-

08-22-2020, 03:42 AM #8Technologist

- Join Date

- Oct 2016

- Posts

- 184

Yep, gcode is actually quite straightforward once you take the plunge. As these machines aren't very intelligent, gcode is just a list of commands for the printer to execute, most of them movement in X, Y, Z and E.

The command that changes the active extruder is T. So T0 is E0, T1 is E1 and so on. https://reprap.org/wiki/G-code#T:_Select_Tool. Extruder == tool in this case. That's all there is to it. What actually happens depends on our hw, but in simplest case Marlin basically starts driving E1 stepper drive instead of E0 (if T1 is issued). With mixing, Marlin runs all the extruders defined by the mixing ratios.

The M163 commands suggested are probably required, it might be that Marlin doesn't define default mixing ratios for the extruders so when executing T0, T1 etc, it crashes because it doesn't know what to do. So add those M163 commands to start gcode or run them before starting a print (not sure if the settings are stored to EEPROM so they might be reset when the board is reset). Can't remember how it was when I was messing with it...

Those M163 commands in the list are the per-extruder all-in settings, i.e. T0 drives only E0, T1 drives only E1...

That last bit seems to be more of an nice-to have feature, not required to get tool changing going. But it seems that with that you'll get an extra menu item where you can change material during printing and do load and unload.

-

08-22-2020, 02:45 PM #9

So I am suspecting I have something wrong in my firmware even though it compiles and the printer otherwise works. I installed repetier and used cura as the slicer and downloaded a completely different test print and even printed from USB instead of SD and got the exact same results. So in configuration.h I have single nozzle enabled but have left mixing extruder out for now. From what i read the mixing extruder was just to enable the m163 and m164 commands for mixing ratios and running multiple extruders simultaneously. While i do want to get to that for now i am just trying to use 1 at a time and thought this was ok. I will try enabling this and see what i get. I am also unsure if i need to do anything to link or multiplex the one temp and or heater for the 3 extruders or if all of that is done with just enabling the single nozzle. I am really at a loss for where my problem is at the moment. At the start of the print I do get all 3 extruders to prime? I don't even know if this is in my slicer gcode or firmware. Why can't there just be a youtube tutorial / walkthrough for setting up the Diamond Hotend with a 32 bit controller and marlin 2.0.5.3? If I can get this figured out I swear I will pay it forward and make one. Enough complaining. Back to the debugging...

-

08-22-2020, 04:54 PM #10

Breakthrough! Thank You Spegelius. So marlin wouldn't compile with mixing extruder and single nozzle and marlin wouldnt compile with mixing extruder and anything greater than 1 extruder selected. SO the only way to configure for the diamond hotend is to have just 1 extruder and leave single nozzle commented out and uncomment mixing extruder and have 3 steppers selected. And I am switching filaments. Been working out some final start gcode gremlins(don't want any retractions or filament unloads at changes) and I think I will get my first Multi Material Print this evening.

https://www.youtube.com/watch?v=hGpCFCEIuXILast edited by AutoWiz; 08-22-2020 at 05:49 PM.

Reply With Quote

Reply With Quote

What's wrong with this prting?

04-14-2024, 05:15 PM in General 3D Printing Discussion