Results 1 to 5 of 5

-

11-12-2016, 11:34 PM #1Student

- Join Date

- Nov 2016

- Location

- West Fargo ND

- Posts

- 9

noob- Prusa cheap knockoff, printed great demo, but cant get anything else to work

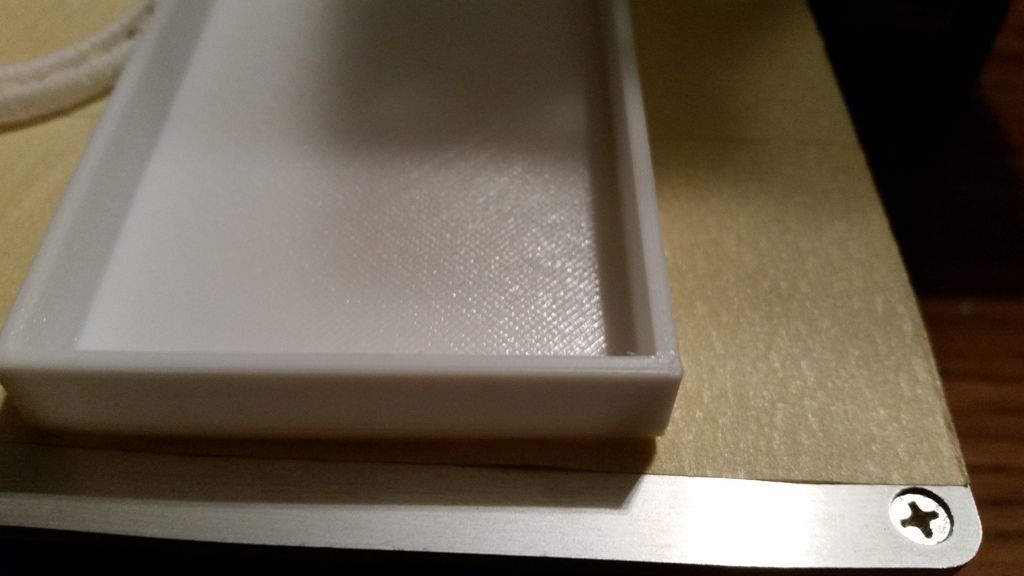

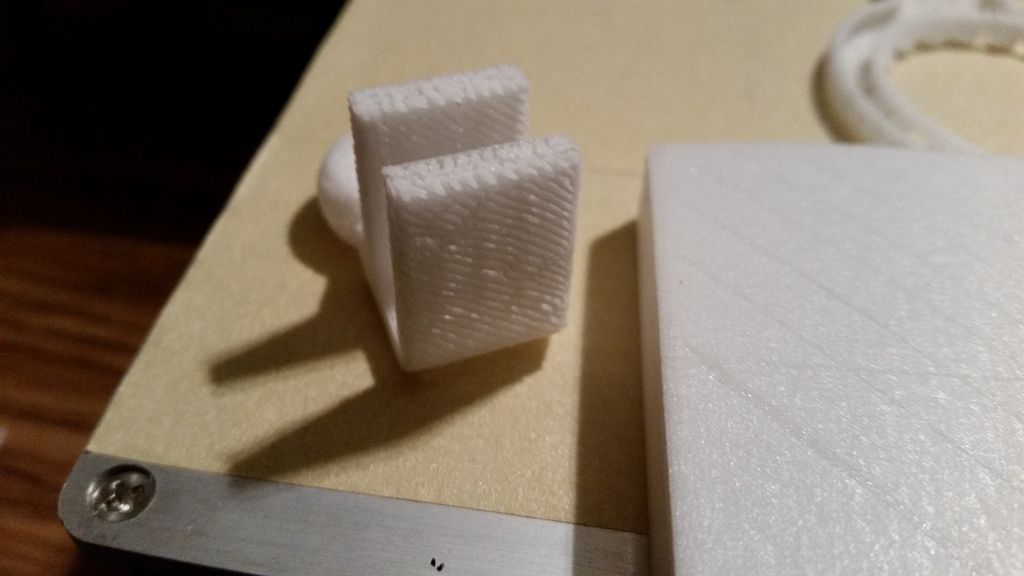

Spent a long time calibrating the bed, the demo file included with the printer was loaded in CURA and exported, no changes (Cura is set for A3 Prusa). The Demo, a small plastic box printed as good as I could have hoped for, I expected problems to start and it was almost perfect. Some small warping on one corner. So i grabbed a few "upgrades" for the printer. the first was a filament guide, then a fan extension. it appears Im getting no outside fill, I get the inside should be hollow somewhat, but its like the inside and outside are the same. No smooth outside. I bumped the shell thickness to 3 and top and bottom to the same. My nozzle is .4 and im printing in .1 layer thickness at a speed of 150 (to fast?).as you can see the demo piece turned out good. But my 2 other pieces look like shredded wheat, not solid at all. Since my demo piece came out so well i have to assume its settings. The demo piece is solid , but my two other pieces are using infill. I am assuming this is not an issue as its the outside having the problems. Same filament same day so should not be that. Hate to make my first post this, but better to use the collective knowledge here to speed up my learning, right? Top pictuer is my first print, 2nd and 3rd should have solid outsides, but niether do. do I need to go past 3 on shell thinkness, when i do in CURA it appears to fill the whole thing.

-

11-13-2016, 08:48 AM #2

If the demo piece printed nicely... It's not the hardware. My bet is the printer is just fine. Most likely you need to get the slicer settings correct.

How did you print the demo piece? Did they give you a .gcode file that you tell the printer to use? If so... Usually all the settings used to make the .gcode file are saved as comments in the file. You might be able to just look at those settings and use those to modify your slicer settings.

-

11-13-2016, 11:15 AM #3Student

- Join Date

- Nov 2016

- Location

- West Fargo ND

- Posts

- 9

It was on the SD card wit the printer all complete. I loaded it in CURA but it appears CURA keeps whatever settings you have set. I noticed no matte what model i loaded all the setting where the same. SO i should be able to look at some comments, that is a great tip. I was loading that model from the SD card and I kept getting the same settings and didn't see a way to "load" my old settings, I will dig around, anybody tell me a way to get to the settings a model has (gcode)?

-

11-13-2016, 11:25 AM #4

well 150 is way way too fast.

knock that down to about 50 or 60

you bumped the shells UP to 3 ?

3 shells and perimeters is my default. For stronger parts I'll do more, but almost never use less.

But looking at it I'd say it's just trying to print much much too fast.

Bear in mind that cura defaults to settings for an ultimaker - bowden printer with very lightweight extruder and no big moving bed.

-

11-13-2016, 01:15 PM #5Student

- Join Date

- Nov 2016

- Location

- West Fargo ND

- Posts

- 9

Well the NOOB was strong with me, there is a setting for CURA on the SD card that came with the printer. I loaded it and all is as close to perfect as I could have hoped for. My first print was 100% from the SD card ( i said i loaded it in CURA first, i didnt) that came with printer (so all correct settings) all the others where loaded in CURA at defaults. I must admit I may be reading speed wrong, im at 30, the 150 was Retraction Speed. So this was all on me, many thanks for suggestions it did steer me in the correct direction.

There is no doubt bed leveling is what i expected, time consuming, and while not hard in theory, but is a real skill, change one corner and all others need tweaking. I can see where this part could really discourage somebody. Every change i made required more, it didn't seem like it was going to end. Otherwise I must admit i think I am having a better then normal experience. I have a knockoff (A6 ANET, was suposed to be a A8, love those Ebay listing with two models listed in same ad, one is huge letters and one in tiny print in specs, again my own fault) It was cheap so my plan is to see how this goes (3-D printing) and upgrade to the REAL prusa (which was the plan to start but is a 3-4 week wait right now).

Oh well rambling mostly because I'm dang happy with the results so far. and again thanks for the help I am sure I will be back for more.Last edited by clok; 11-13-2016 at 01:27 PM.

Reply With Quote

Reply With Quote

QIDI Slicer "Plater" is...

04-12-2024, 02:21 AM in QiDi 3D Printer Forum