Results 1 to 5 of 5

Thread: FLSUN i3 DIY kit

-

09-08-2016, 11:00 AM #1Student

- Join Date

- Sep 2016

- Location

- Barcelona

- Posts

- 5

FLSUN i3 DIY kit

I'm new in 3d printing. I start with this printer:

http://www.flsun3dprinter.com/index.php?route=product/product&product_id=51

This is a very cheap printer, that include all the required basic parts.

First of all, the manual is not the best. You have to pay attention and think about how it should work. For example:

PROBLEM 1:

The X axis belt tensor, is not properly explained. Because the screw must be free movement, I solved with hot metal to increase the hole.

PROBLEM 2:

The unilateral bearing is not moving free at the closest position, I solved again with a hot metal to edit the support piece.

PROBLEM 3:

The X axis is not firm because the Smooth pole is not properly fixed and it's moving (see picture). I am waiting for manufacture answer.

Onthe other hand, there are included several extra screw (I hope...). So you can print some extra piece and use these screw.

EXTRA PIECE:

Kossel_Filament_Spool_Holder_2020

http://www.thingiverse.com/thing:209294

FLSUN Kossel Delta Power Supply Mount

http://www.thingiverse.com/thing:1532391

Solid and Smooth 1kg or 5lb reel holder (Ionly use thi filament guide and the cleaner idea).

http://www.thingiverse.com/thing:374368

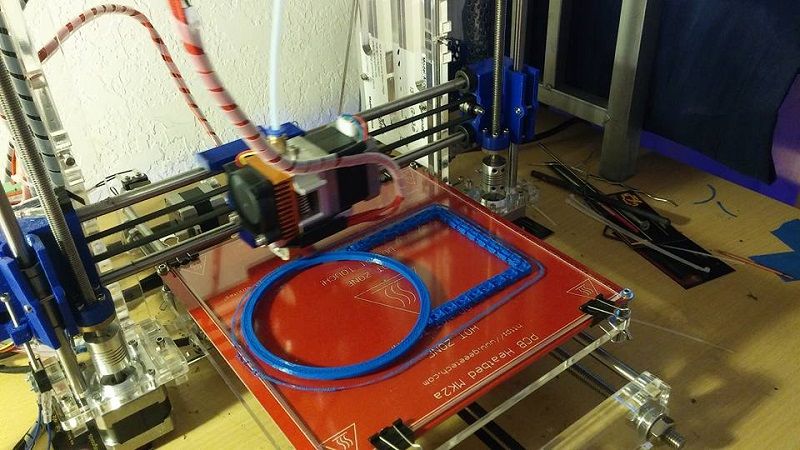

Finally here a current picture:

Do you have it? Share your information about it (configuration, problem, solution, improvements...).

Thanks!

-

09-10-2016, 10:40 PM #2

for problem #3 I believe there is a small hole in the printed end just above the smooth rod. To me this looks like a place where a set screw should be applied. Skill level is the great modifier or handicap for these cheap printers. If you are good with your hands, patient and meticulous than you can buy the cheapest of printers and make it print like a professional machine. If you occasionally drool on yourself and forget to wipe then maybe you should find the more expensive printers that require less on your end to achieve a quality print.

-

09-11-2016, 05:41 AM #3Student

- Join Date

- Sep 2016

- Location

- Barcelona

- Posts

- 5

Yes! there is a small hole where I can place a screw. I tried, but the problem is that it go across a plastic piece. It is not fixed hard enough.

I have 2 options to try now:

-Drill a hole on the metal shaft and place this screw.

-Create a printed 3d piece to place like an final shaft.

I am totally agree about cheap printers. I enjoy setting it properly. Maybe, this knowledge could help someone.

Thanks for your answer!

-

09-11-2016, 10:40 AM #4

Or you could get a stop collar like one of these..

http://www.ebay.com/itm/8x-Drill-Dep...MAAOSwnipWaViy

and apply them like this..

-

09-12-2016, 12:25 PM #5Student

- Join Date

- Sep 2016

- Location

- Barcelona

- Posts

- 5

Yes! Good idea! Is it hard enough to support the bealt tension?

Reply With Quote

Reply With Quote

Print not sticking to base plate?

Yesterday, 01:26 PM in General 3D Printing Discussion