Results 111 to 120 of 132

Thread: My 3 Color Mixing Printer

-

08-23-2020, 12:02 AM #111

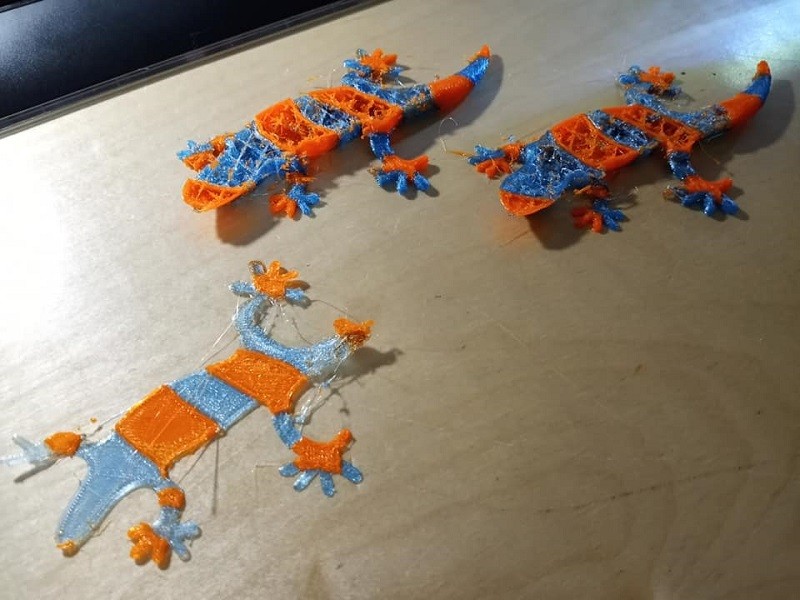

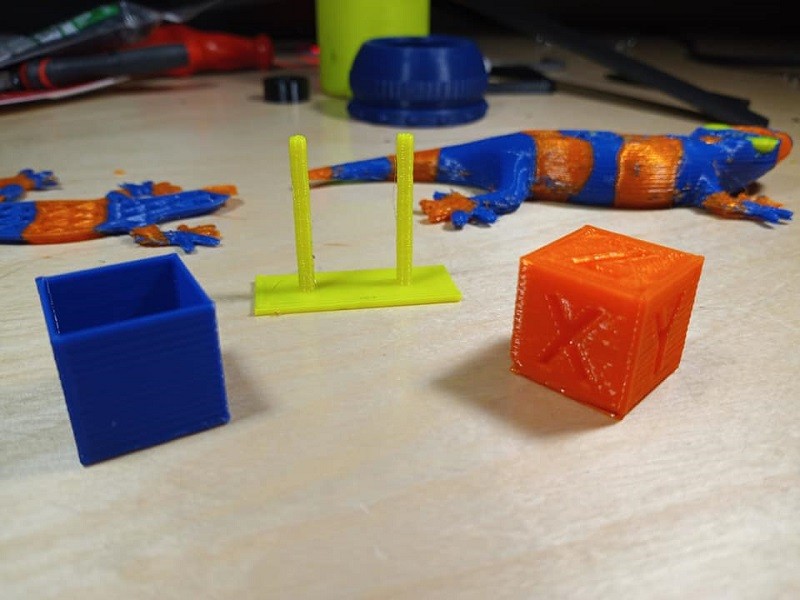

Well Fishpaste! Everything was going great. I didnt get to a finished print yet but i am getting closer. Here are the results of my first 3 attempts..

And then it happened. I decided to shorten the PTFE tubes to reduce friction and before I started playing around with the retraction settings. I shortened the tubes and fed in the first filament all the way with the nozzle hot. I should have let it cool first and fed all three in and then warmed it and fed each one in a little bit at a time. The filament went in and squeezed out the 2 unoccupied heatbreaks past the transition zone and into the cold end. I have my work cut out for me to clear this jam..

-

08-23-2020, 08:48 PM #112

I slept on it and decided on a careful approach to clearing the jam. One by one I removed each heatsink and placed a piece of a silicone mat blocking airflow to the heatbreak allowing it to heatsoak to the 240c temp of the nozzle..

Upon teardown I realized there is no thermal paste on them threads on the cold end side. This is important. And I just happen to have the best thermal paste money can buy. Thermal Grizzly kryonaut. So a little of this needs to go on the threads of each heatbreak only on the cold end side..

-

08-24-2020, 12:31 AM #113Technologist

- Join Date

- Oct 2016

- Posts

- 184

Alright, progress! So the M163 helped then? Kinda strange that Marlin doesn't properly enforce setting the default mixing ratios...

I might have done the same thing, bit luckily I didn't get a full blockage. The clone cyclops I have is PTFE lined all the way to the block so I guess it wont do that.

-

08-24-2020, 11:36 AM #114

The diamond hotend came with thermal tubes that accepted PTFE liners but i swapped them out for all metal micro swiss heat bricks so I dont have to worry about printing with the higher temps. That might have worked against me here. lol. I am getting closer. I need to calibrate E steps, and then run the linear advance thing and then retraction settings. Maybe find out how fast the extruder can feed filament and then correct print speeds based off that. BUT i am getting there, and TY again Spegelius..

-

08-24-2020, 12:57 PM #115Technologist

- Join Date

- Oct 2016

- Posts

- 184

Yeah, all metal heatbreaks are more prone to jams, but as long as they are kept cool they should work... I've had my share of problems with heatcreep on all-metal hotends and every now and then the problem pops up, mostly with bowden systems. Actually yesterday I had this happening, a red PLA started printing bad on very small details so I added a filament oiler with a dab of olive oil and it the problem went away. The filament had probably sucked some moisture as I there was an occasional popping sound while printing so the proper fix would have been to dry the roll. But filament oiling can help, although it's bit messy and not sure if it weakens the part. According to this at least PLA shouldn't suffer: https://www.youtube.com/watch?v=yY7ZrVE8eks.

-

08-26-2020, 10:27 PM #116

Ya i am back to struggling with jams again. Although no where near the level I was having this problem before. I might need even more cooling. I am printing at 230c which brings up another point. The diamond hotend has a 15mm deep hole in the center at the top for a heater cartridge. It comes with a 20mm cartridge that sticks up a bit and I had to track down a 15mm cartridge which I did. And I have this huge chunk of hotend with a tiny little heater cartridge and yes it climbs in temps quite slowly. It is becoming clear to me that this diamond hotend is just a poor design and even if I get it to work it will be underwhelming in its slow all around performance. I am not giving up on the 3 color mixing. It is just that I have found a newer style of a 3 color mixing hotend and I am curious if it corrects any of the problems of the diamond hotend. The Geeetech 3 in 1 mixing hotend is a little bit more at ~$45 vs the ~$15 I paid for the diamond hotend. It has what looks like a removable nozzle. It holds 3 heater cartridges. And I can't find any reviews on it. But Geeetech is selling a 3 color mixing printer and this is it's extruder. I already ordered this and when it comes I will order 3 high precision 30w heater cartridges and a temp sensor from E3D. I will keep going with the diamond hotend for now but in the longrun I am excited at a faster nozzle warmup time and hopeful that the newer design will be less prone to clogging. https://www.aliexpress.com/item/4000...E&gclsrc=aw.ds

-

08-28-2020, 07:08 PM #117

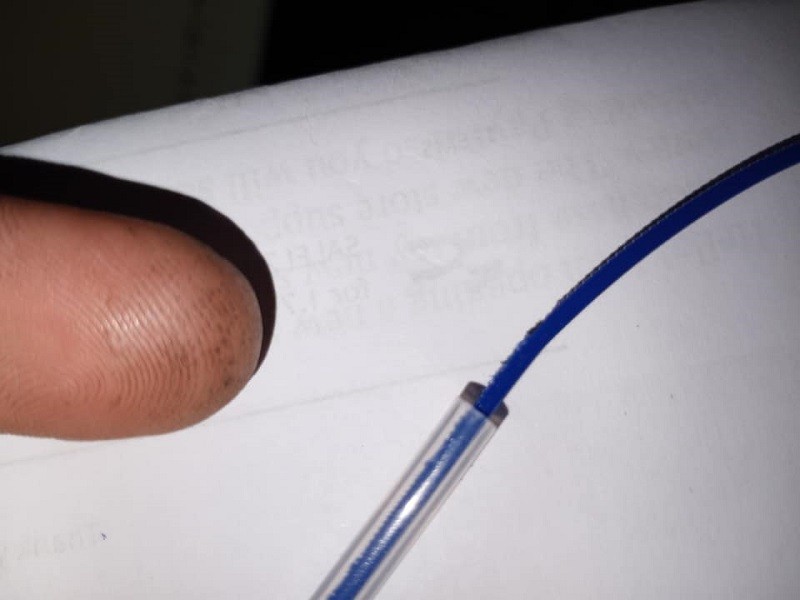

Well I did some research on the max safe working temps of the ptfe tubing and 250-265 isn't bad. Then I found this blue ptfe tubing that can handle up to 300c. I got excited and ordered 2M of it. It is supposed to be reduced friction on the inside and a slightly smaller id also to better control retraction distances. This tubing right here: https://www.ebay.com/itm/Tough-Tube-...wAAOSwRUJeszwo . I wanted to put the heatbreaks that came with the diamond hotend back in it and run these high temp tubes and continue my push to get this diamond hotend to print in good quality. Sadly I threw away the heatbreaks when i swapped in the all metal micro swiss counterparts. So i'm not going back to ptfe lined heatbreaks without further investment in something i have lost confidence in. I hope the Geeetech part shows up soon.

-

08-28-2020, 11:26 PM #118

-

08-31-2020, 09:51 PM #119

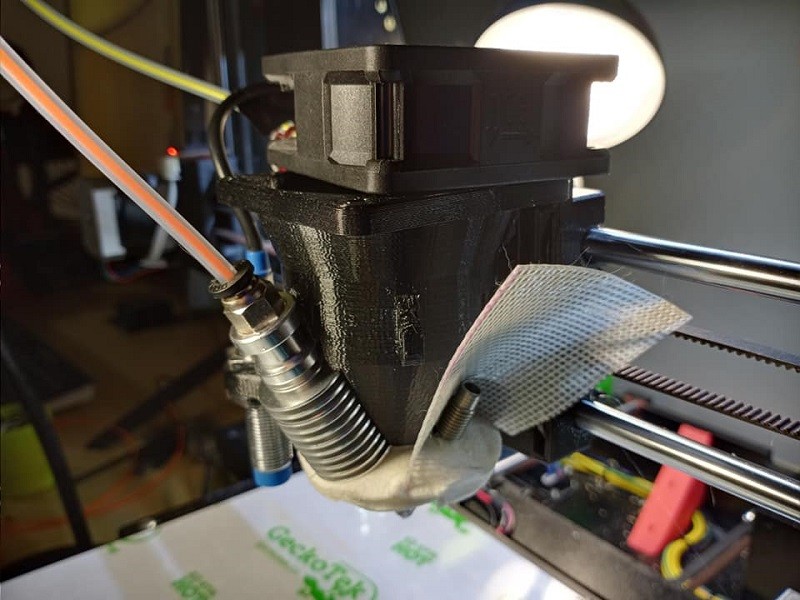

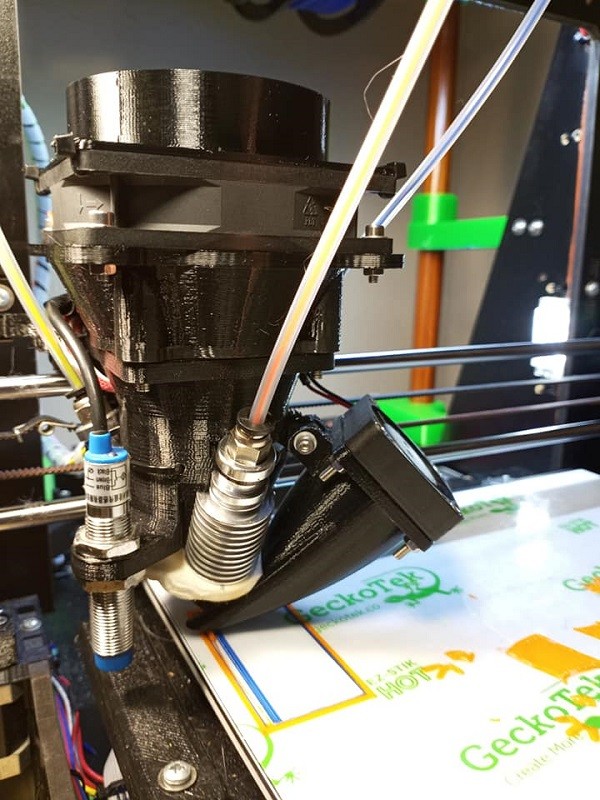

So despite not having the original heat breaks to put back in the diamond hotend I am still trying to get results out of this all the way up until the new hotend arrives. I already got the high temp(300c) blue ptfe tubing but I am going to wait until I swap the hotend to install the blue ptfe. For now I have upgraded the 60mm fan to an 80mm fan blowing air across them 3 v6 heatsinks. This extruder is getting large..

-

09-01-2020, 07:22 PM #120

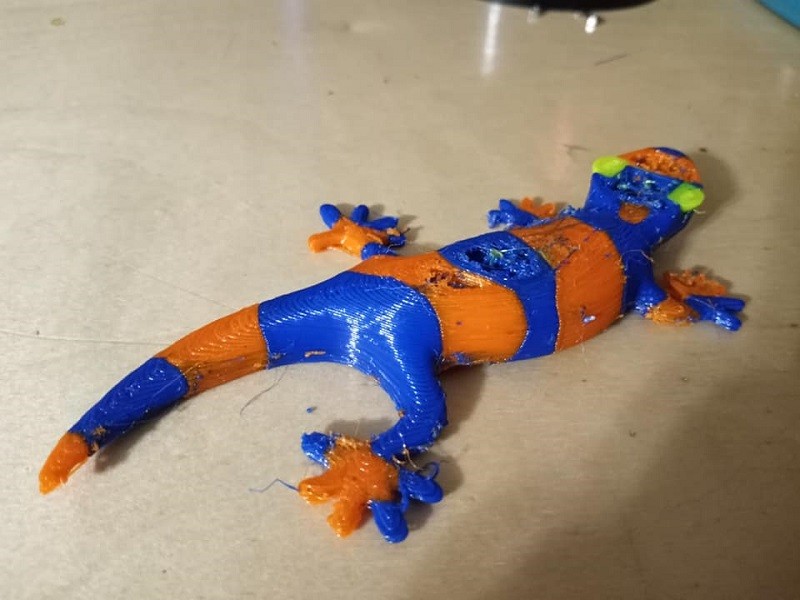

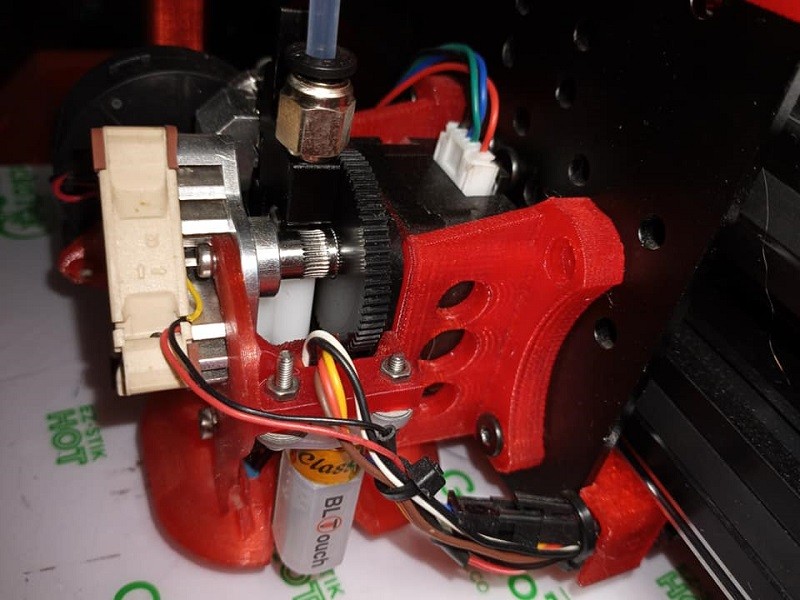

I have another issue with this printer that is the 3 cheap ebay titan extruders. I tried to save some change and it is costing me. Most hobbed gears have a groove or a channel where the filament rides giving the hobbed gear more surface area of the filament to bite on. Here is an example. This is a genuine E3D titan Aero on my Big Red printer..

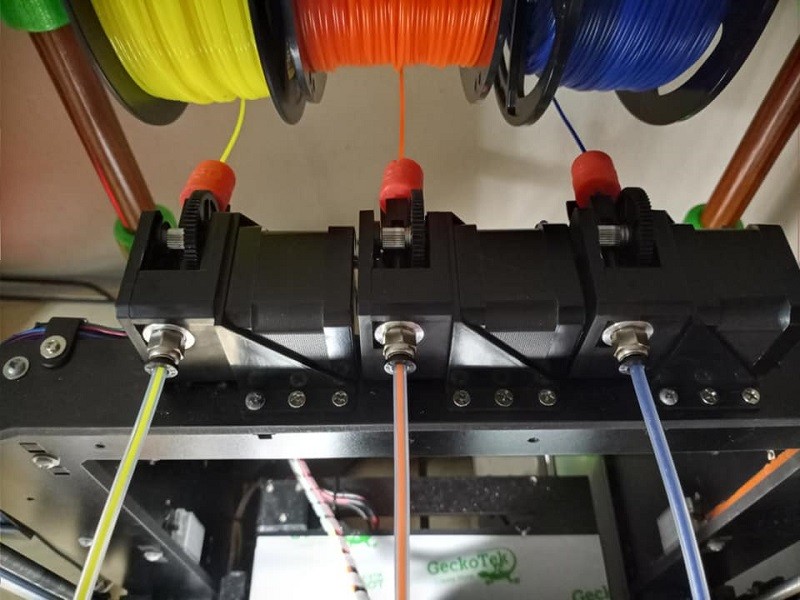

Unfortunately what comes on the 3 cheap titan extruders is really just a gear with fine pointed teeth all the way across. This is the 3 titan extruders currently sitting atop this machine..

These straight teeth bite into the filament in a very small area in comparison and so the just chip off and dig holes in the filament which is and has been frustrating to me. This is what they keep doing to my filament..

So along with the geeetech 3 in 1 hotend and the blue high temp ptfe I will also be swapping the 3 titan extruders for 3 genuine bondtech extruders ordered from Sweden. This will be a painfully simply conversion and will look much the same when I am done. I will just be feeding filament in a much better manner. So i am back to waiting on a host of parts the extruders are coming express FedEx so maybe they wont take so long. The geeetech 3 in 1 extruder advertises 60mm/s print speeds and I very much mean to test and push that limitation as hard as I can. I want a multi material machine that can print like my single filament machines do.

Reply With Quote

Reply With Quote

Print not sticking to base plate?

Yesterday, 01:26 PM in General 3D Printing Discussion