Results 1 to 10 of 132

Thread: My 3 Color Mixing Printer

-

09-06-2016, 09:29 PM #1

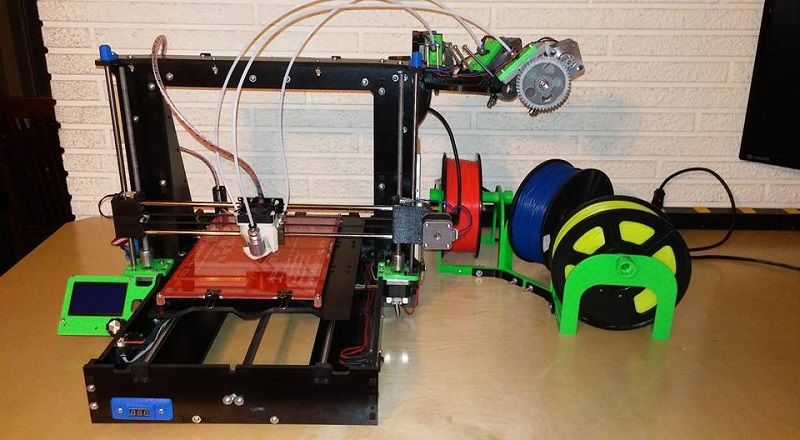

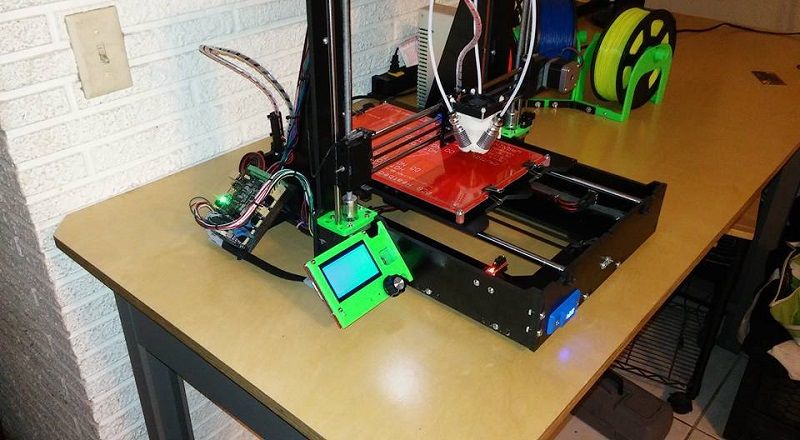

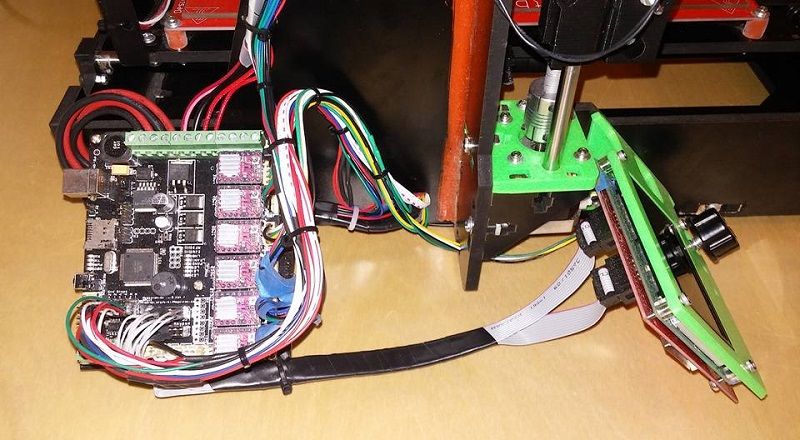

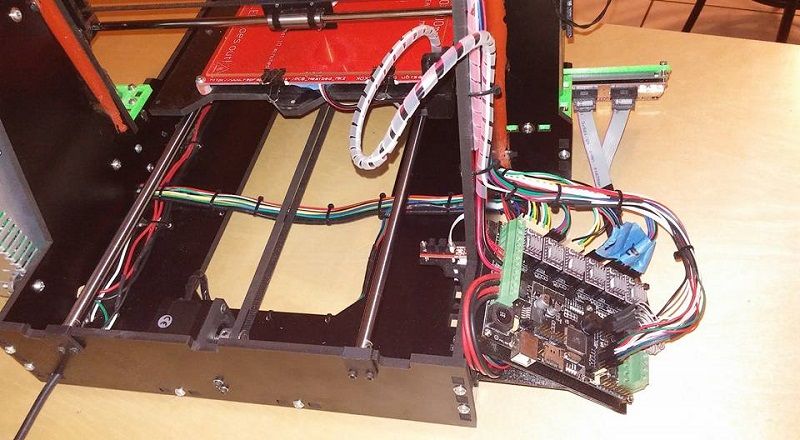

My 3 Color Mixing Printer

Hello. I started with a geetech prusa i3 pro b or c I purchased from ebay. I detailed the building of that here:

http://www.digitalcorvettes.com/foru...d.php?t=269457

And then I got started on making my own printer. pictures of that can be seen here:

http://www.digitalcorvettes.com/foru...d.php?t=270130

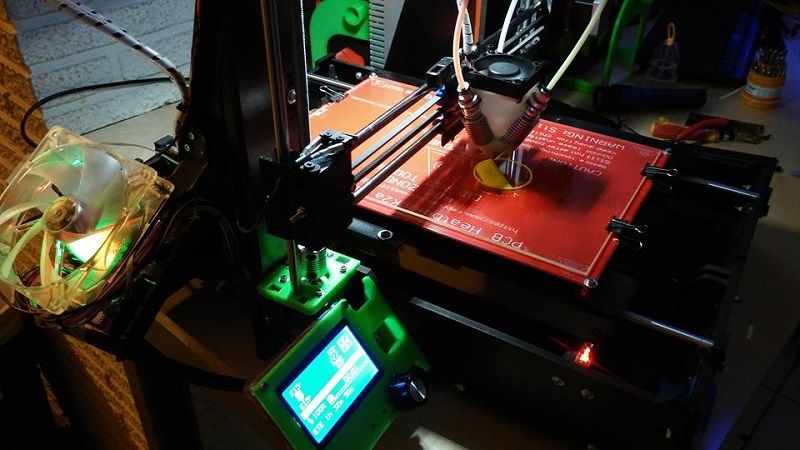

This is my new custom built printer..

-

09-16-2016, 05:20 PM #2

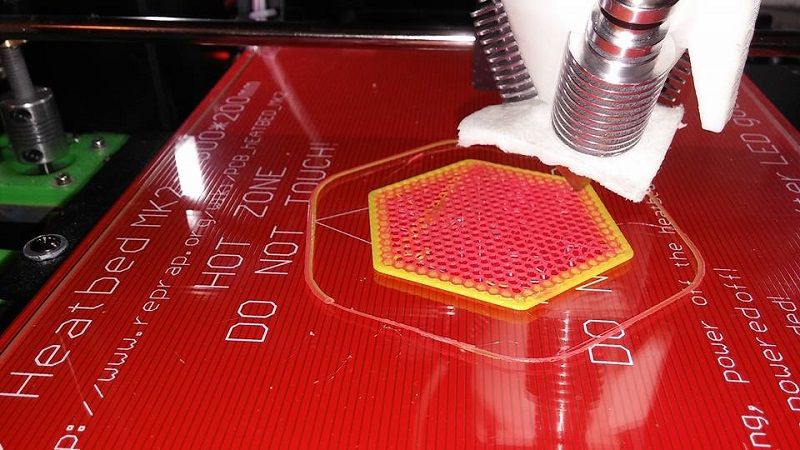

So this new machine I created can print pretty decent..

And it can print well in any 1 color that I start the print off in..

But what is happening is that whatever 2 filaments sit in the beginning unused and at temp, the filaments seize to the all metal heatbreak. I read about the ideas of cooking oil and turning off retraction and don't really like those ideas. For now I have 3 ptfe lined heatbreaks coming. I know this will remedy my problems for now but this is gonna be no good later if I wanna start printing in abs.

-

09-17-2016, 07:15 AM #3

you can actually buy 3 in 1 ready made mixer extruders.

Might be easier in the long run.

Though I like the chunky way you've made your own :-)

-

09-17-2016, 12:25 PM #4

I wanted to build one because I found this 3 in 1 out mixing extruder on ebay and thought it would be awesome to have. But as the project progressed I didn't find too many other models of a 3 filament printer to go off of or at least loosely base my plans off of. So everything you see is what my mind could come up with. I mounted the 3 spools 45 degrees from each other and did the same with the wade extruders and then tilted each one back 45 degrees and ran the filament the specific way I did so its path would keep an arc that is compatible to the natural bend in the filament from being wrapped around the spool. Maybe I over thought that. This is only my hobby. I am used to building on a larger scale:

http://www.digitalcorvettes.com/foru...d.php?t=271354

http://www.digitalcorvettes.com/foru...d.php?t=242081

http://www.digitalcorvettes.com/foru...d.php?t=241858

http://www.mp3car.com/forum/general/...al-time-tuning

http://www.mp3car.com/forum/mp3car-t...controller-bcm

I could post a bunch more links. I have a lot of build threads. I love to build. I will continue to revise this printer again and again first to make it function well, And then to make it take up less real estate, and finally I will try to make it easy on the old eyes.

-

09-24-2016, 04:20 PM #5

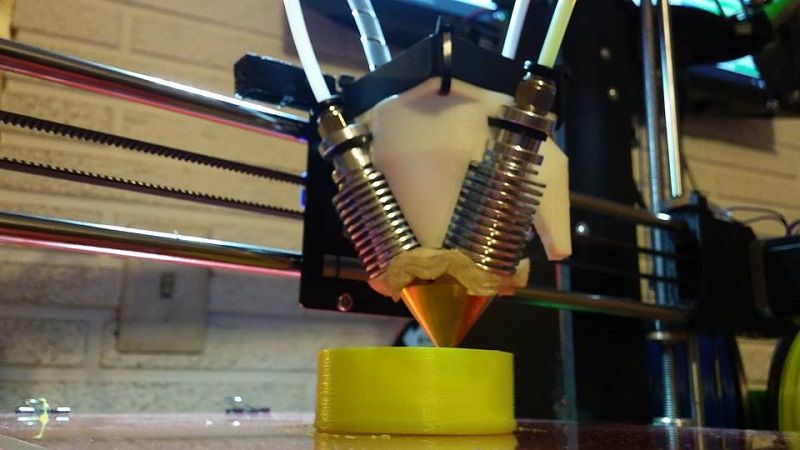

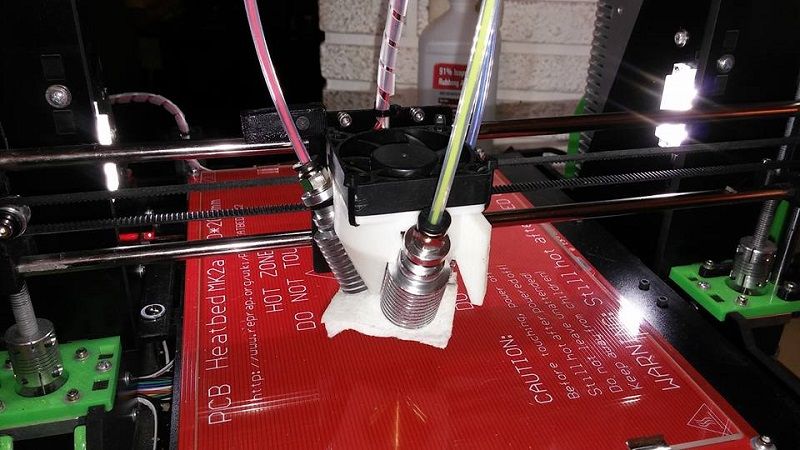

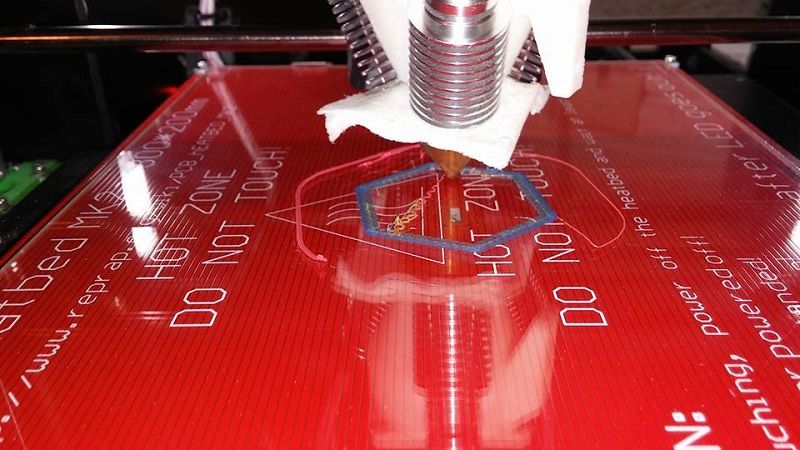

So my new printer has been having filament jamming issues. I have tracked this down these 3 little pieces called "heatbreak" They are the threaded sleeve that attaches the heatsink to the hotend and filament passes through this sleeve. These sleeves are metal and the hot filament seems to be glueing itself to the walls if these sleeves. here is a picture of the heatsinks removed from the hotend..

In the above picture I am 2/3 of the way to my solution. The sleeves with the narrow part on them are solid metal with a 2mm hole for filament to pass through. I got 3 heatbreaks for mk8 extruders. these are ptfe lined. I pulled out the ptfe lining and cut them to the proper length. Look how deep the ptfe tube slides into the all metal heatbreak..

Now look at how far the same tube slides into the sleeves I got with the ptfe lining removed..

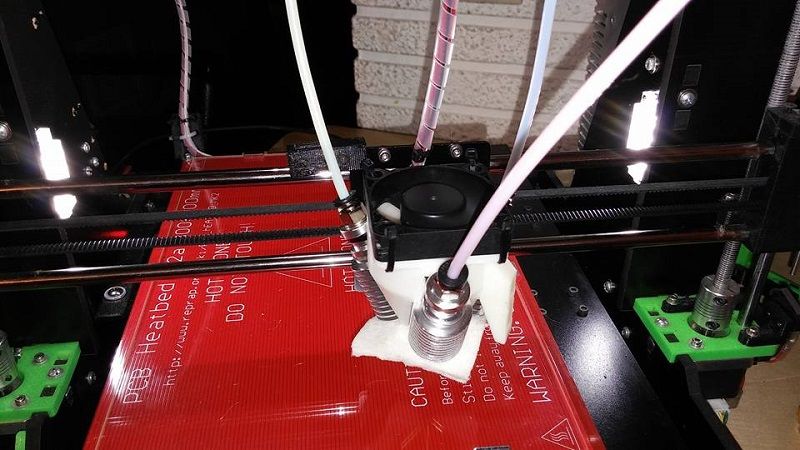

All the way to the very tip. Now there is a reason for this. the thin part of the all metal part in theory is supposed to promote a good well defined small area transition zone where the filament is in a semi molten state. This might have benefits for abs printing where ptfe lined tubes aren't good all the way to the hotend, but I am only using pla and plan on getting or building an enclosed machine before I even try to satart printing abs. So this seems like a best possible solution for me. But there is one more problem. The sleeves I am using are m6x1.0 and the old all metal sleeves are m6x1 on the hotend side and m7x1 going into the e3d heatsink. Simple fix with a m6x1.0 thread repair kit..

Instead of thread locker I use some high quality thermal paste here..

and here..

And I put it back together with some clear ptfe tubing instead of that white stuff. I think it looks better..

Hopefully I will have some pictures to post of some awesome multi colored prints soon.

-

09-25-2016, 05:51 AM #6

This is a really cool build thread. Do you have any pictures of a finished print?

-

09-25-2016, 02:30 PM #7

Really nice work on this. I am really interested in how it works once you get it all working right.

Great job!!Editor in Chief

Bitsonline

Tips Appreciated But Not Expected

BTC: 16wxHvKd3oU6SVjv6FrenqhkvRmc8t7sPy

DASH: XqyaWxH896j9YeV1M35Gzb5gmRPmPbNDGq

-

09-25-2016, 06:12 PM #8

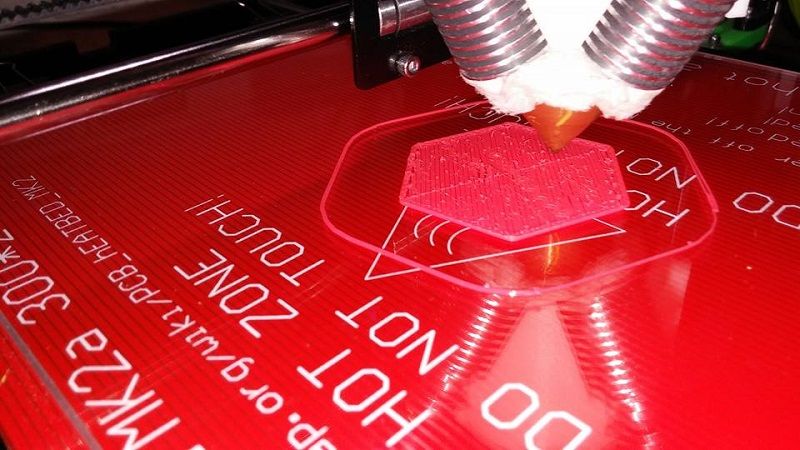

I printed out a thin small cup with each color separately. I have no pictures of those finished but they did print and rather nice. But this jamming issue has kept me from a single color print. While there is a curve for me to understand how to actually mix the colors or have multiple extruders pushing filament at the same time, I am keen on how to print with multiple extruders. After the most recent mod everything started out right, and then jammed..

I smelled something and think that maybe this clear ptfe tubing might have a lower melting temp than the white stuff. So this evening I am tearing it all back down to inspect my theory and if so to switch back to the white tubes

-

09-28-2016, 10:29 PM #9

Tore the print head back down again. Found what I expected..

The filament glued itself to the inside of the clear ptfe tubing I got and installed when I modded the heatbreaks. Simple solution. re installed the other white ptfe tubes I originally had on..

And I am trying to print something out tonight

-

09-28-2016, 10:42 PM #10

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 01:59 AM in Tips, Tricks and Tech Help