Results 1 to 10 of 102

Thread: Itty Bitty Double FLEX Extruder

-

04-06-2015, 03:01 AM #1

Itty Bitty Double FLEX Extruder

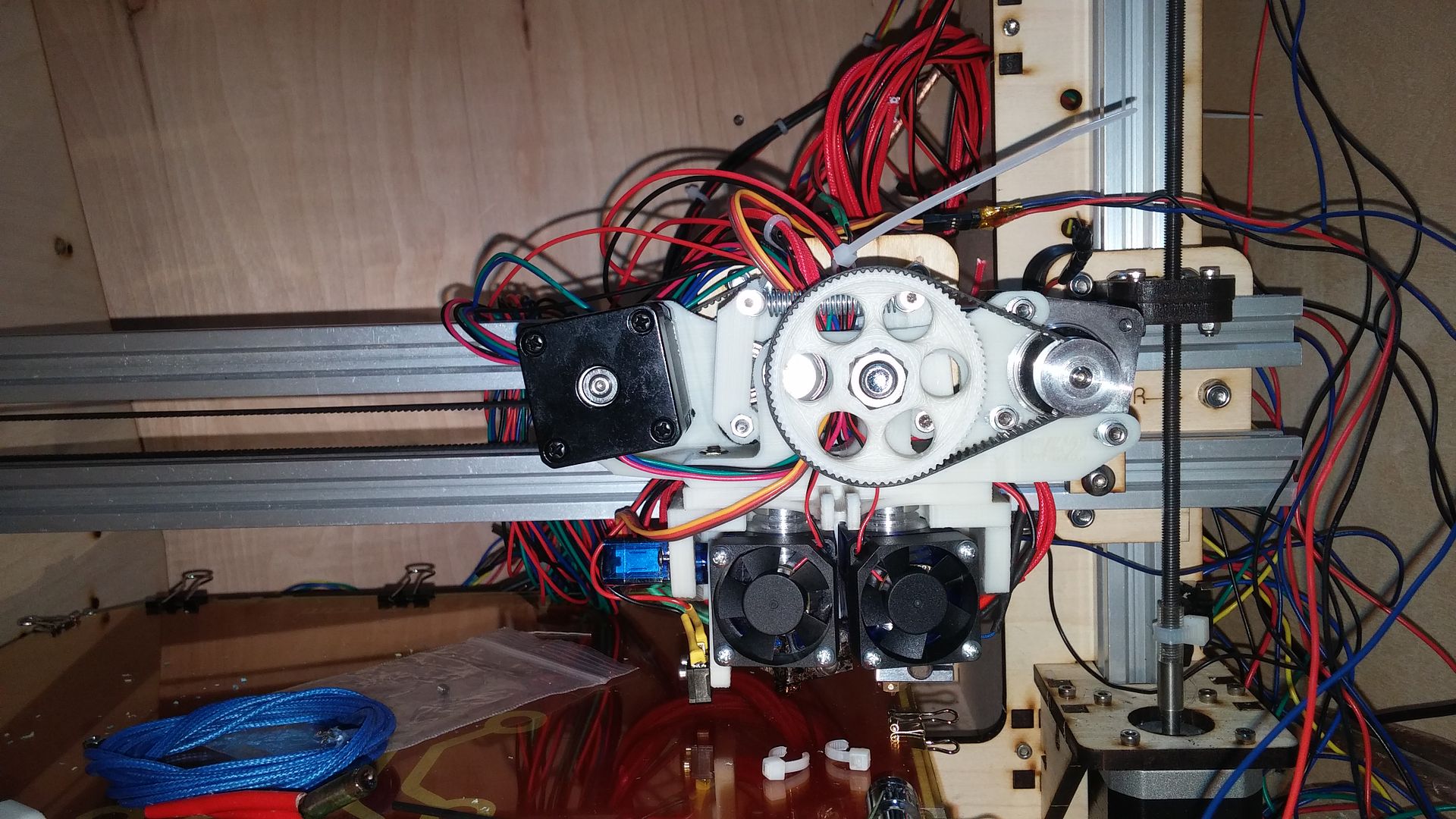

Introducing the Itty Bitty Double FLEX Extruder:

IBDF-UpperRight-h.jpg

This is an evolution of the previous Itty Bitty Double Extruder with wider nozzle spacing and a shorter filament path to accommodate both E3Dv6 hot ends and flexible filament. It uses the same hardware kit as the Itty Bitty Double Extruder, so if you already built one, you can print out the parts and use the hardware you already have.

Key features:

- Designed for Hexagon or E3Dv6 hot ends on 27mm centers

- Short, straight filament path to accommodate flexible materials

- Uses the same hardware kit as the original Itty Bitty Double Extruder

- NEMA 14 motors

- Silent GT2 belt drives with printed pulleys

- Integrated servo Z probe

- Cam-lock idler bearing pins

- Uses standard MakerFarm hobbed bolts

- Lighter than a stock Accessible Extruder

- Integrated hot end cooling

- Mounting hardware for Prusa i3v printers

Please use this thread for questions and discussion.

*** A hardware kit is available ***

Get it here

Links:

- Info and printable parts: http://clough42.com/designs/itty-bitty-double-flex/

- Hardware kit: http://clough42.com/go/product/IBDE-HK

- Assembly instructions: http://clough42.com/go/itty-bitty-double-flex-assembly

- Firmware setup: http://clough42.com/go/marlin-firmware-setup

- Calibration: http://clough42.com/go/double-extruder-calibration

- Thingiverse: http://www.thingiverse.com/thing:757864

Last edited by clough42; 04-20-2015 at 12:07 AM.

-

04-06-2015, 04:23 AM #2Engineer

- Join Date

- Nov 2014

- Posts

- 522

I was wondering when this would go live :-)

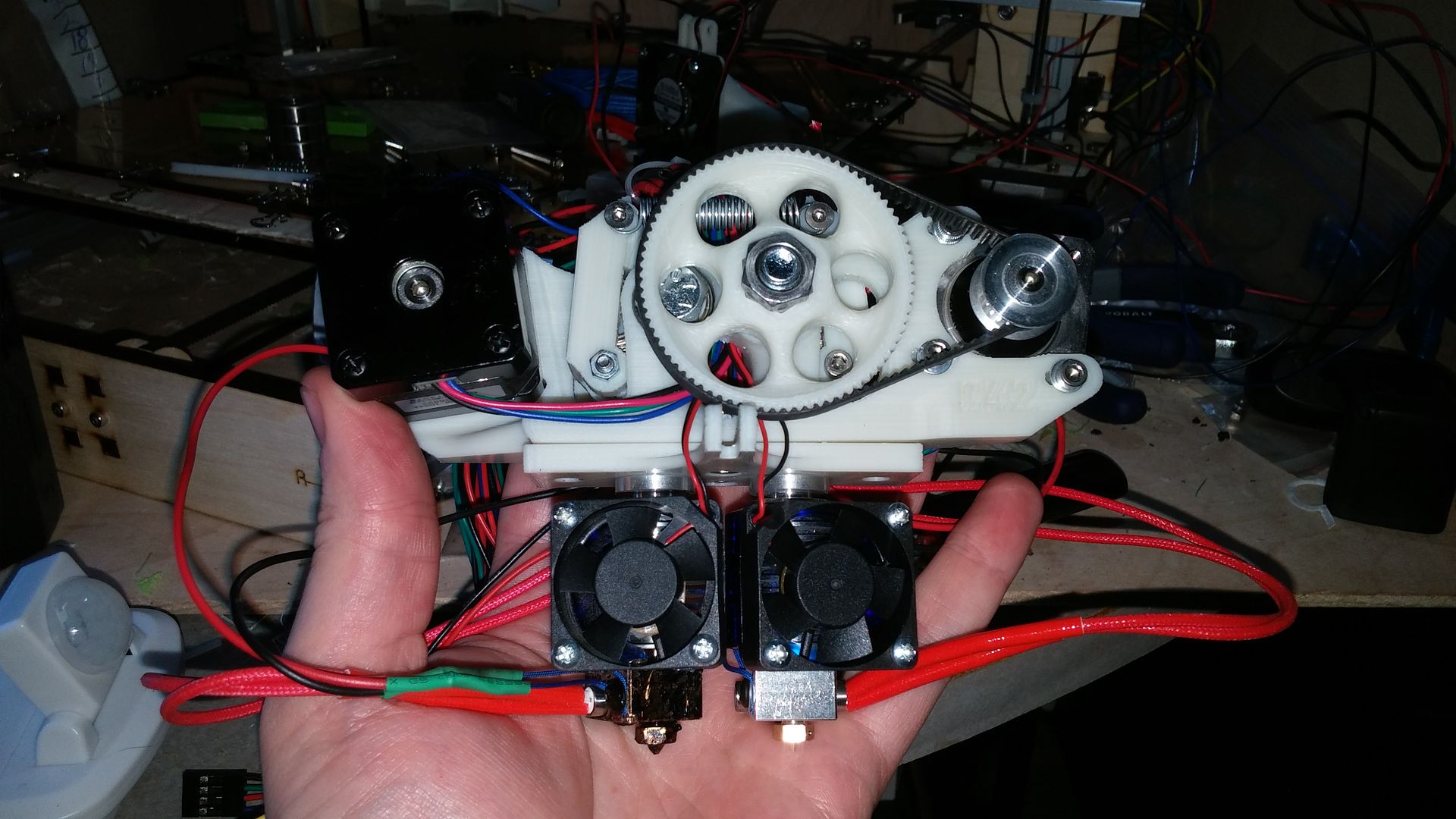

dual E3D V6's This is the first alpha a little bit has changed on it, but it's still a live pics vs a cad drawings.

just had wiring to go

all together but in my hand

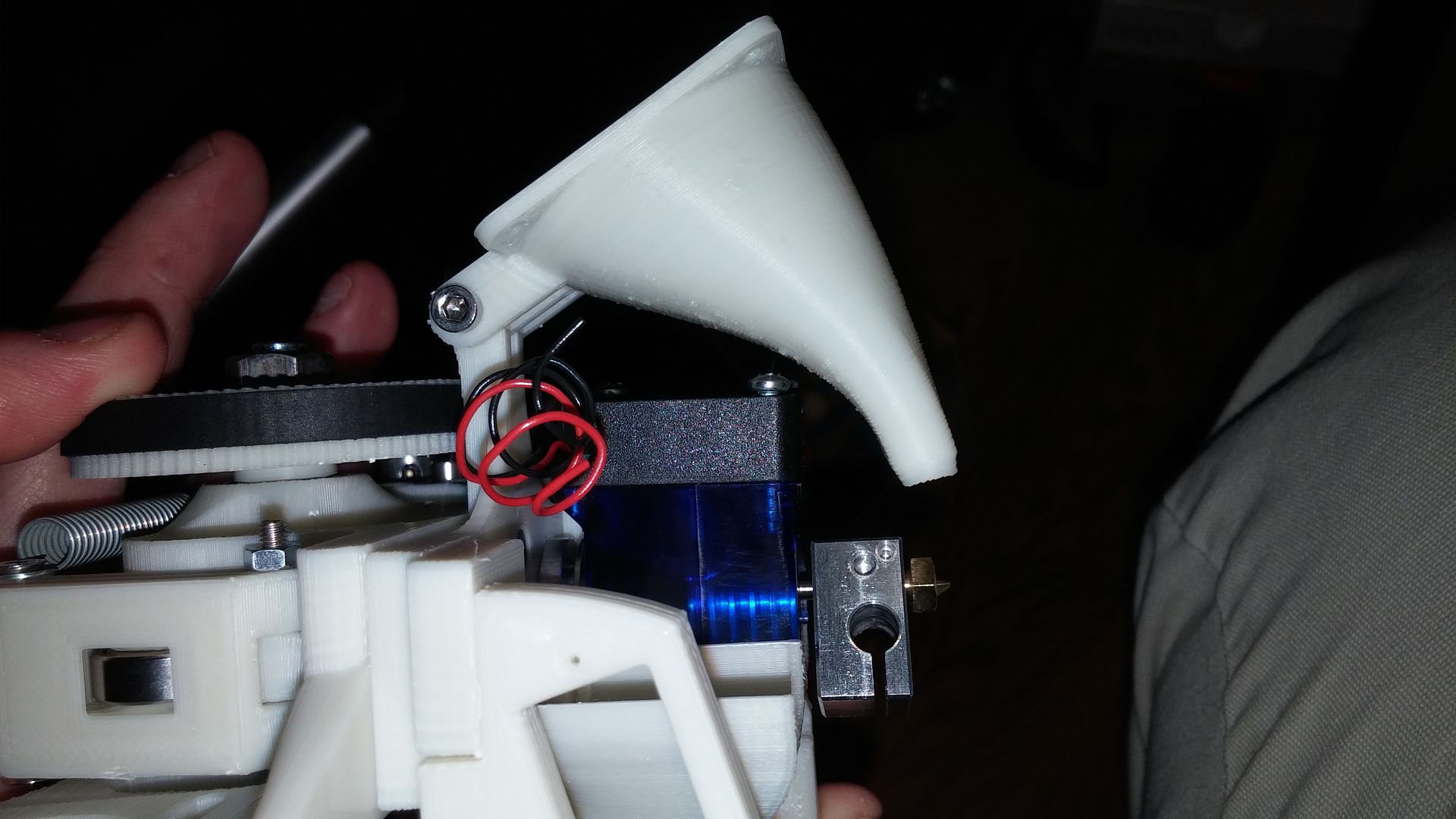

checking positioning of part cooling duct

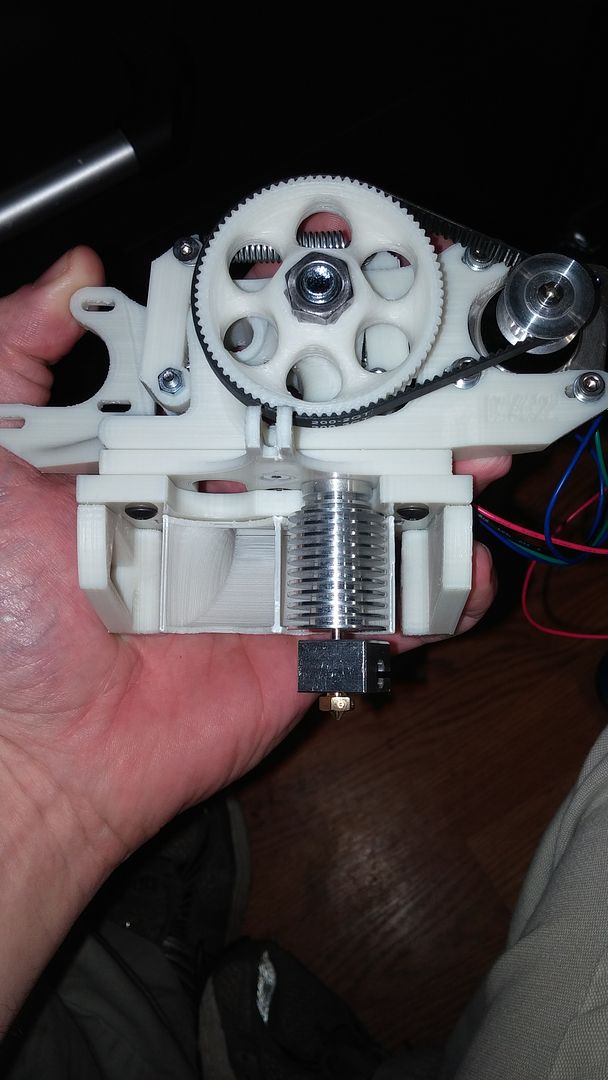

dry fitting with the 2nd E3D while the other was still printing

-

04-06-2015, 05:26 AM #3Student

- Join Date

- Dec 2014

- Posts

- 21

Hi Clough42, are integrating those changes into the single version? Or can it allready br used with e3dv6?

-

04-06-2015, 07:57 AM #4

Great job C42!...One thing I would suggest to add to your website instruction page is the use of the PTFE Tubing for the 1.75mm setp. I should have mine all setup by tonight..

-

04-06-2015, 10:31 AM #5

-

04-06-2015, 10:37 AM #6

Here are some photos of my setup. The big difference between the release version and the one sniffle is running are the cable management tie points.

And here's a totally ridiculous test print. It's a 1:10 short course truck tire. The black material is ABS and the red is NinjaFlex. Printed at 30mm/s with .2mm layers, it took 14 hours. I photographed it on the 8x8 printer bed for scale.

-

04-06-2015, 11:06 AM #7Technician

- Join Date

- Mar 2015

- Location

- Palo Alto

- Posts

- 63

Dang, and I just finished printing and dry fitting the itty bitty dual. I guess the obvious questions to decide whether to redo it or not while waiting for motors are: How much am I going to print flexible material and how much x-axis travel is lost? Only I can answer the first part. Can you make sure I'm not off the deep end in my analysis of the second part?

My machine currently homes with the endstop as far right as it will go and the nozzle directly over the edge of the glass. It travels roughly 238mm (10" model) before the carriage hits the left z axis parts, but there is another 10-12mm of glass that is not used. Switching to dual extruders without doing anything else, the left nozzle will home at x=10 (itty bitty dual) or x~=13.5 (itty bitty flex) and the right nozzle will be the same distance off the glass in free air (-10 or -13). At the far left position the left nozzle may actually use the currently dead glass, but the right nozzle will max around 228mm (itty bitty) or 225mm (flex). So in either case the left nozzle will have basically the same travel I have now, but the right nozzle will limited.

If I can redesign the endstop I may be able to move the left nozzle back to the edge of the glass at home and so would get actually more x travel than I have now (hopefully the full advertised 250mm), but the right nozzle will still be limited to max x=228/225mm. Can't say that I care much about the 3mm loss on the secondary nozzle for itty bitty double vs itty bitty flex, but will have to keep in mind that only the left nozzle can reach >225mm.

Does that sound right?

All of this assumes, of course, that the nozzles are centered on the carriage and that nothing else (motors, etc) interferes with the frame.Last edited by jasay; 04-06-2015 at 11:20 AM. Reason: grammar

-

04-06-2015, 07:29 PM #8

C42, what Marlin should we be using for the flex?

-

04-06-2015, 08:22 PM #9

initial setup...waiting on new thermistor that broke...

-

04-06-2015, 08:23 PM #10Technician

- Join Date

- Mar 2015

- Location

- Palo Alto

- Posts

- 63

Based on the link at the bottom of the itty bitty flex page on his site I would say this one:

https://github.com/clough42/Marlin/t...3v_double_flex or if you prefer the direct link to the zip: https://github.com/clough42/Marlin/a...ouble_flex.zip

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 01:59 AM in Tips, Tricks and Tech Help