Results 1 to 6 of 6

-

03-30-2015, 10:45 PM #1Banned

- Join Date

- Jan 2015

- Posts

- 306

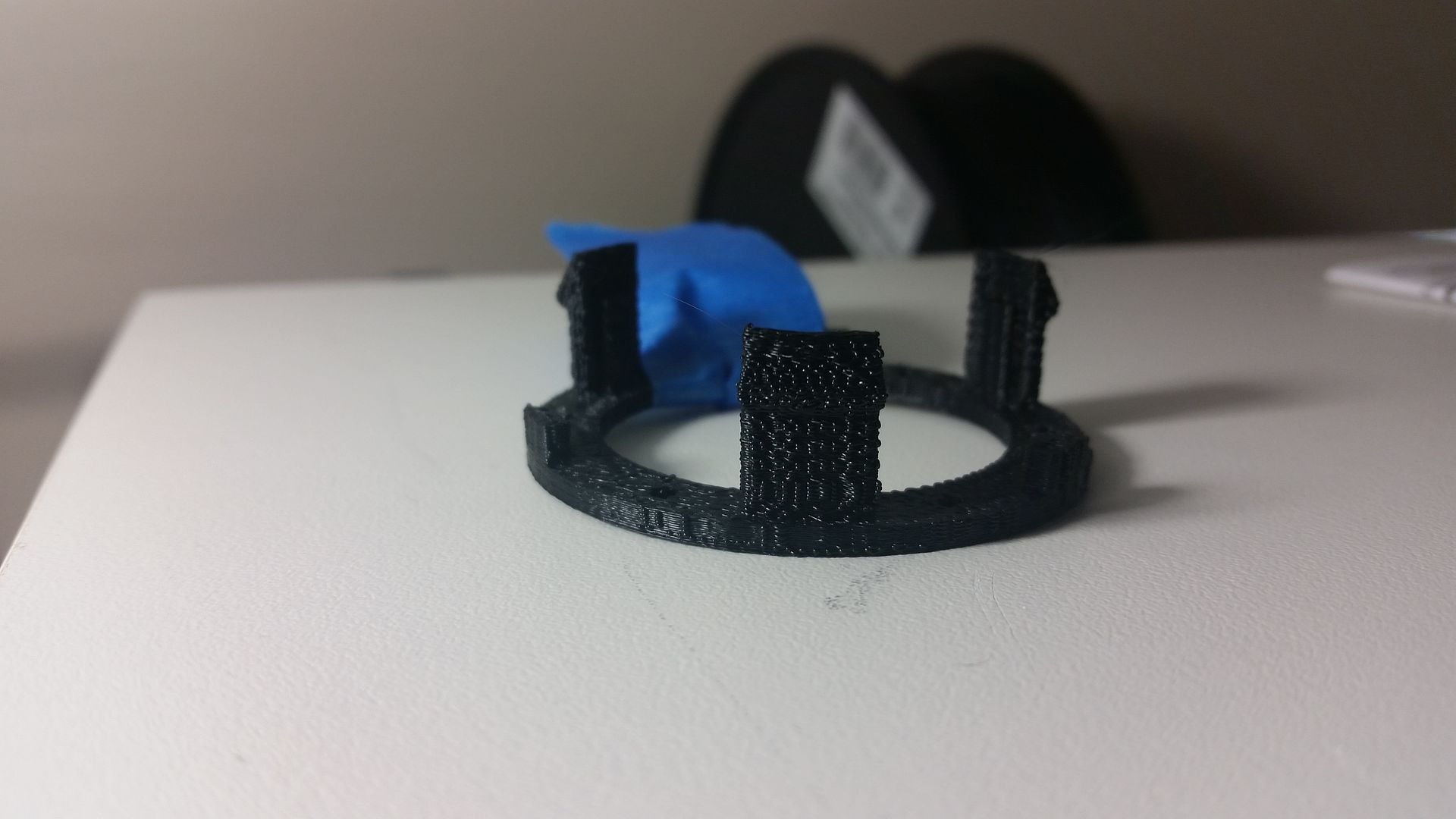

ABS prints are coming out terrible

Hey guys, look at this. Please help me diagnose.

Is this over extrusion?

Thanks

-

03-30-2015, 11:40 PM #2Banned

- Join Date

- Jan 2015

- Posts

- 306

EDIT: I didnt figure it out, I thought it was over extruding. It is something else causing this.

Last edited by DBFIU; 03-31-2015 at 12:14 AM.

-

03-31-2015, 02:25 AM #3

Have you tried to lower the temperature of extruder?

-

03-31-2015, 05:58 AM #4

ABS is one of the most commonly used, and most versatile materials available in 3D printing today. If you're new to the scene though, it can be a bit daunting to start with. However, the payoff is worth it.

In order to print with ABS, you need a temperature controlled bed. The recommended bed temperature for ABS is 110. Instead of printing directly on the glass, it’s better to print with PET tape. This makes it easier to clean the bed after you’ve been printing for a while, as you can simply remove the tape, clearing any leftover adhesive or filament.

Having your bed level and extruder at the right height is extremely important when printing on tape. If your extruder is too far from the glass your ABS simply will not stick. If the extruder is too low the glass it will completely block the extrusion of material and may cause a jam after extended periods.

You should also make sure that you have an adhesive of some sort. ABS requires something to bind itself to during the first layer of the print. The most commonly used adhesives are glue sticks, ABS slurry, and hairspray. We prefer hairspray because it’s easy to apply and smells nice. Make sure you get the kind with a plastic base.

-

03-31-2015, 06:24 AM #5

I don't believe this has anything to do with bed temperature, but rather the bumpy or blistery texture of the vertical shells.

In my experience, those bumps are usually from infill moves or priming, causing material to flow out past the exterior perimeter.

Corrections include printing slower, doing fewer pulses of prime/unprime, and/or adding more vertical shells (perimeters).Last edited by Davo; 03-31-2015 at 07:02 AM.

-

03-31-2015, 12:58 PM #6Banned

- Join Date

- Jan 2015

- Posts

- 306

Reply With Quote

Reply With Quote

QIDI Slicer "Plater" is...

04-12-2024, 02:21 AM in QiDi 3D Printer Forum