Results 1 to 10 of 166

Thread: New 12" user and I am LOST!

-

02-05-2015, 08:59 AM #1Engineer-in-Training

- Join Date

- Feb 2015

- Posts

- 371

New 12" user and I am LOST!

So, my first experience in 3D printing was with an Afinia printer at the school I teach at. It is a very small printer and works great out of the box. I was able to make some very nice parts that come out very finished in appearance. the top is very smooth. The success I had lead me to the Makerfarm and my desire to own a larger printer for myself. Colin has been great and has emailed me frequently with answers to my many requests.

My trouble is, I cannot get this printer setup correctly. Here is what I have...

Makerfarm i3V Prussa 12" model

Rumba electronics

graphical LCD

Mac OS

Google Sketchup 8 to create models

Slic3r and configs from the build guide

pronterface

Here are my issues...

1) Cant connect to pronterface. I had trouble with the firmware and had to download the arduino ftdi drivers. I am able to get that to work in order to install firmware. When I startup pronterface, nothing appears in the port menu. Weird. I went back to the arduino and it now will not connect. I try various things and swap the cable out, with intermittent success. I cannot find a pattern. I reinstalled pronterface with the most current version and bingo, it worked. I had control of the printer, sent it g codes, etc... Now, just a day later and nothing! I connect and it gives me baud rate issues or it will just say connecting but never do anything. Sometimes the usbserial connections show, sometimes they don't! Which one do I use? tty?

2) I cannot get the Z axis set right. In order to get a good first layer than is smooshed into the glass as pictured in the build guide I have to lower the Z endstop so much, that when i home the printer the nozzle smashes into the heatbed. I tried all of the steps in tutorials online without success. My first attempt was to align the z axis endstop using paper. I would lower the z by hitting auto home and adjust till it just holds the paper. If I hit autohome (using LCD) the z will raise and stop at a different point (higher) WHAT? if I immediately hit autohome again it will return to the spot I set. Happens like that repeatedly. Should hitting autohome return the z to the same spot every time?

3)I followed Collins advice and just set the Z to be almost touching the bed using paper and leveled the bed first making sure the x carriage was level. I then ran a test print and looked at the first layer. The nozzle was about 1-2mm off the bed and just loosely spitting out filament. It needed to be smooshed more so I stopped the print and lowered the endstop. Reprint. I did these steps until I was happy that the first layer was printing correctly. Now, when I hit autohome, the nozzle smashes into the bed. URRRRG.

4) When I was able to print a part, it was horrible looking. I am using slicer and the configs provided in the build guide. The afinia printed parts that had very finished top surfaces. Very flat, like glass. The Makerfarm didn't print tops well at all. Very rough.

I haven't the experience to diagnose these issues. I have spent countless hours surfing the net and understand half of what I read. I am not familiar with terminal and some of these suggestions are throwing terminal commands out which I am intimidated by.

So, where do I start? HELP! I feel like I have made a terrible investment and should have gotten a more proprietary machine.

-

02-05-2015, 09:26 AM #2

Hi tsteever, Welcome. You came to the right place, I am sure there are folks who can help. NOT sure how many use macs, and the folks using Rumba are not many but I think it will get figured out for you. I have ramps and linux so not much help, but for one thing the paper thickness is the way to go for leveling. I use the home or z home in pronterface, and have not really used the LCD for that, you could see if that gives you anything different. As for your part, I have no idea what an afinia looks like, I will look it up, but I am sure it took tuning to get to the way it is printing now. I am confident we will help you figure this out, and you will get TONS of support here. These guys rock!

-

02-05-2015, 09:34 AM #3Engineer

- Join Date

- Nov 2014

- Posts

- 522

These machines are meant for the tinkerer, I also have a 12" printer it prints great now but it took some effort to get it there.

That being said I'll throw a few suggestions out there and a few questions.

What are you trying to print with ABS or PLA?

Ok here we go...

#1) try different USB ports. If that doesnt work it could be a bad USB cable, It happens that they go bad sometimes quickly, as they are usually cheap chinese cables. Beyond that i don't have a mac so i won't be much help.

#2 & #3) OK bed leveling... Manual bed leveling can be a major pain, and must be redone every so often when prints start getting off... when you do get it right you will know. Before you level the bed you need to level the X-Carraige to the Z-Axis so that when you use the print head to level the bed you are using something level to level with. To do this i use a set of digital calipers i got from lowes, and used the depth gauge to measure from inside one of the z-motor bolt heads to the top of the z nut trap on the X carriage, on both sides. these values need to match

After you level the X-Carriage, I personally use a feeler gauge but others use paper, you want the paper to have resistance when you drag it under the nozzle. It is generally suggested to go around twice and always start the rounds in the plastic spacer corner. If you are adjusting using the Z-rods for height you aren't doing it correctly. You must adjust fine tune Z height with the micro adjusting bolt for the Z endstop. When you home the printer it should go to a position in the corner that looks the same as if it were about to start a print.

What surface are you printing onto? It must be a flat surface like glass and be secured using binder clips(if you are using window glass(2mm or 3mm from lowes ~$2.50 a sheet) i suggest using micro binder clips($1.50 or so for 70 at walmart) they take up less bed space and you don't have to remove the wings on the 12" bed you shoudl use at least 5 per side to make sure the heated bed is held formly to the glass and is kept flat against the bed so that you adjustments are actually seen when you adjust the bed.

4) Once you actually start printing parts part of the looks of the part come down to more calibration. proper e-steps in the firmware are important, a good average is somewhere around 870-890. Once that's set you can do micro calibration with your Extrusion Multiplier. Sometimes it is also the Slicer that is used, If the extruded filament looked a little thin then try using Cura it tends to extrude a little thicker, and has less options so it is a little easier to learn on. You will find that once you have the bed mechanically setup properly the slicer plays a really big roll in print quality.

Feel free to ask questions we will all help as much as we can. I promise you that with some effort on your part we will get you printing well i promise.

all of the bluish parts were printed on my 12" makerfarm printer using MakerGeeks Glow in the Dark ABS, we will get you there :-)

-

02-05-2015, 09:53 AM #4Engineer-in-Training

- Join Date

- Feb 2015

- Posts

- 371

Thanks!

I am using ABS for now as that is what I had used on the Afinia. The Afinia, by the way, needed no tinkering. We took it out of the box, made sure the bed was level and printed. They outline a procedure where you move the nozzle to a paper width away from the bed and set that as the nozzle height. My assumption is that is a Z-offset value? I will attach a pic of a Afinia printed part and a mother part I attempted to print on my Makerfarm. You can see a very noticeable difference int he top layer. Both printed with ABS.

For my surface, I am using glass from the hardware store and i spray it with the same hair spray Collin used in his vids.

I regret buying the Rumba as I thought it would be an upgrade but it appears that since very few people use it I am at a disadvantage.

As for the LCD movement, Collin told me not to use that as it can get the Z axis out of sync. I just can't figure out why it homes to a different z position when I hit autohome? SHouldn't it always stop when the endstop is activated?

My big thing is where can I get some pronterface help? Most of the time people are making suggestions they tell me to move something using pronterface, completely ignoring the fact that i cannot get it to work! I guess I shouldn't cram so much into one thread.

-

02-05-2015, 09:58 AM #5

tsteever - another option for getting some timely help is seeing who might be around on an IRC channel set up for Makerfarm discussions. Participation varies, but there's usually a few people on board. We have found the IRC to be very helpful for rapid-fire Q&A from new people. There is one user who frequents the IRC that I believe has been using pronterface on a Mac.

EDIT: Forgot the link to the thread discussing the IRC: http://3dprintboard.com/showthread.p...rfarm-printersLast edited by printbus; 02-05-2015 at 10:05 AM.

-

02-05-2015, 10:05 AM #6Engineer

- Join Date

- Nov 2014

- Posts

- 522

no your fine we'll do our best to help, I have a rambo board and was the first on the forums to have one i think so i literally had to figure everything out on my own. That being said it is entirely possible to get great prints but thats the difference between reprap and more closed source options. I would suggest printing an auto leveling setup early on if you dont want to deal with bed leveling.

As to you connection to the printer I would try different USB ports on the computer as well as a new cable

As far as the ABS i would suggest using a pretty high print bed temp around 120 especially if you don't have an enclosure, the slightest breeze can warp the print.

-

02-05-2015, 10:06 AM #7Engineer-in-Training

- Join Date

- Feb 2015

- Posts

- 371

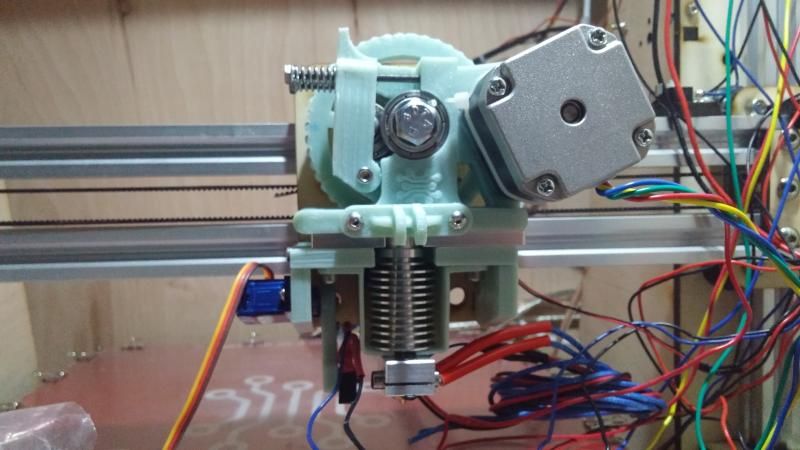

Here are some pics...

Comparison of Afinia part on left and maker farm on Right. Both ABS and .4mm tip

Yuk! Blobs on side of print and the holes did not fit the printer even after I cleaned them out.

Nozzle height (end stop) set with paper. When it prints the nozzle is 1-2mm off the bed surface!

This is the skirt after setting the z end stop using paper

Blobs of material on the top of the print

-

02-05-2015, 10:10 AM #8Engineer-in-Training

- Join Date

- Feb 2015

- Posts

- 371

The auto leveling is something I want to do but Collin told once setup correctly it shouldn't be needed. I can't even get it setup! Hopefully the Rumba is capable of auto leveling as every thing I read seems to be ramps. Wish I could do ABL, but I can't even print the parts!

-

02-05-2015, 10:13 AM #9Engineer

- Join Date

- Nov 2014

- Posts

- 522

the abl makes life easier i have 2 under 2 i needed it

that looks like your esteps is way too high, i would lower your extrusion multiplier some to see if that thins out the filament some

-

02-05-2015, 10:14 AM #10

I've never heard of using AutoHome on the LCD causing the Z axis to get out of sync, and that makes little sense. You are right - unless there are wiring shorts or other issues, the final position of the all axes after a home action is driven by the endstop switches.

The MakerFarm printers are only equipped with endstop switches at the minimum positions. There have been variations of Marlin around that have the inputs for both the minimum endstops and the maximum endstops enabled. In a few cases, there have been issues with the unconnected maximum endstop inputs floating to an active state and being detected by the electronics. Whether that could be applicable to your case, IDK, but it'd be something we could help you look at.Last edited by printbus; 02-05-2015 at 10:34 AM.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Yesterday, 01:59 AM in Tips, Tricks and Tech Help