Results 1 to 10 of 26

Thread: looking to build a machine

-

05-06-2017, 01:40 AM #1Student

- Join Date

- May 2017

- Posts

- 16

looking to build a machine

Hey all, not sure if this is the right section but nothing else seemed to fit for this question. So right now I have a Lulzbot Mini but am finding that its 6"x6"x6" build area keeps getting in my way. I know that it is possible to make a larger frame for the Mini and change the settings in the program but I kinda want to leave this one alone and just build a larger machine. Ive got a source for NEMA 17 motors along with the lead screws and slide shaft and hardware. But im a total n00b when it comes to finding what controller to use. Ive searched and searched read multiple "best boards etc..." lists but an still unclear of what I would really need.

so far, to help here is a general idea of what I would like to build, keep in mind this is not set in stone.

300x300x300 build area (possibly larger)

24v operation

heated print bed

CoreXY gantry

Control LCD

Im not looking for the cheapest parts. I dont mind spending a little more to get something better. I mainly do ABS and Nylon materials. I do plan to build a full enclosure for this machine to help the materials laminate better. Any help is greatly appreciated.Last edited by OutcastZeroOne; 05-06-2017 at 02:43 AM.

-

05-06-2017, 09:45 AM #2

why not just get a kit ?

Have a look at the folgertech ft5 - fits all your requirements, full kit runs at around $499

https://folgertech.com/products/folg...3d-printer-kit

300x300x400 print volume.

All metal cage construction - so very easy to enclose.

The other option and another $200 but with larger build volume is a delta kit:

The he 3d kt280 $560 (with store discount) https://www.3dprintersonlinestore.co...3d-printer-kit

280mm base by 600mm build height.

The kt200 - same kit - but around $199 and 200 x 300 build.

If nothing else, looking at the build videos will show you what bits you need to source to build a machine from scratch.

-

05-06-2017, 03:24 PM #3Student

- Join Date

- May 2017

- Posts

- 16

well, because so far my build cost is about $60 for parts

my main issue is lack of knowledge on the main print controller. I do already own a Arduino Mega 2860 and screens for it, but not sure if thats the best option. I know i can always upgrade this later once I get the machine built.

-

05-06-2017, 09:32 PM #4

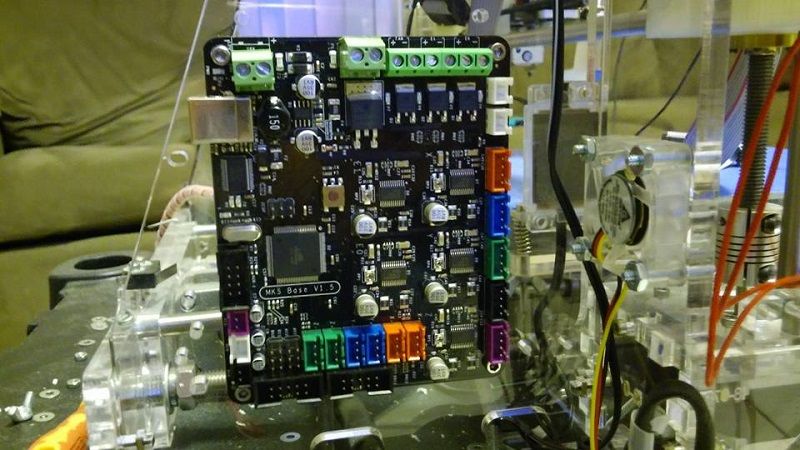

Because of a stated large print area and required large print bed, you should consider a 24v controller and power supply. Most controllers will do 12/24v but this is the first thing you should identify in your hunt. Running 24v will also allow you to use quiet tmc2100 stepper drivers with 1/256 interpolation. These drivers when paired with 400 step/rev. or 0.9 degree stepper motors and a 0.2mm nozzle makes for a high def printer. If you wish to chase down something like this then you also know you want a board with sockets for drivers and not integrated. The mks base boards like this 1.5 I recently swapped into my geeetech i3 have integrated stepper drivers that can not be upgraded or changed. here is what that looks like..

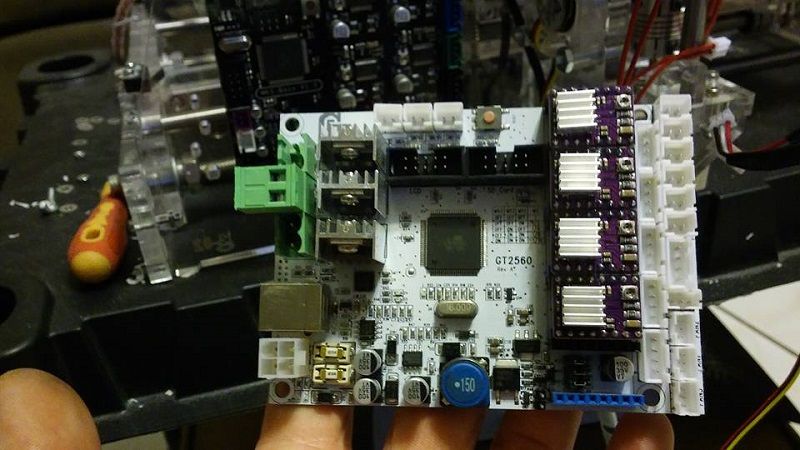

The integrated drivers are a4982 drivers that are 1/16 micro stepping. The board I took out of the geeetech printer was a GT2560. I had swapped from the a4988 drivers that came with it to the better 1/32 micro stepping drv8825 drivers..

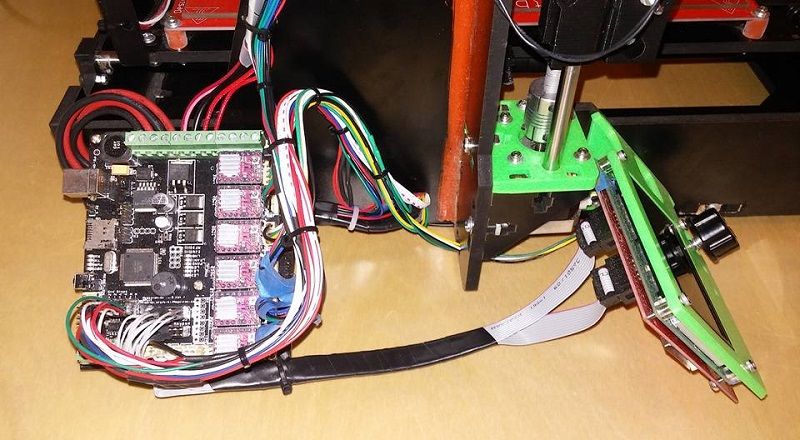

Because this swap went from 1/32 micro stepping to 1/16 micro stepping, I had to upgrade the stepper motors themselves to keep the same resolution or number of steps per mm. As far as processing power goes both of these boards are very similar if not exact as with most. The difference becomes features offered by each manufacturer. I have recently started liking the mks boards because they support touchscreens and wifi modules. In my homemade printer I used a megatronics v3 board because it had 6 stepper driver sockets and I was trying to make a 3 in 1 out extruder work..

http://3dprintboard.com/showthread.p...Mixing-Printer

The tevo black widow I am building currently came with a mks gen v1.4 board. The gen boards have stepper driver sockets unlike the more compact base boards. And just like the mks base, The gen boards support touchscreens and wifi modules. But again when it comes to processing power actually driving the 3d printer They all are driven by an Arduino mega / ramps merged board. They all use the same marlin firmware just configured differently. Until you get into the smoothie boards but I think all that is better for the delta's.

All of the above mentioned parts I purchased very affordably off of ebay. So affordable were these parts that trial and error was more fun than pain. Start a build thread and post up pictures of your progress, please.Last edited by AutoWiz; 05-06-2017 at 09:44 PM.

-

05-07-2017, 12:19 AM #5Student

- Join Date

- May 2017

- Posts

- 16

Very cool, thank you for the info and comparisons of the boards. Right now I am not really planning on any high detail projects, never realy been my thing, so I may stick with the 1.8° nema 17's I was planning on getting since they are also 24v and on sale for $3 from an Electronics Surplus recycler I deal with. I will do a bit more research into some of the boards. Also that Mega 2560 I have is not a clone, so i have faith in its quality. I also have the LCD and touch screens for it but not sure I can configure those for this as I am still learning how to use them aswell

but, you know. If i can do full car stereo systems integrating the Logic7 amp on a brand new BMW or the full fiber optic amps of a Mercedes, Im sure I can do this too

but, you know. If i can do full car stereo systems integrating the Logic7 amp on a brand new BMW or the full fiber optic amps of a Mercedes, Im sure I can do this too  Yes, I work at a high end car stereo shop and am "that crazy project guy"

Yes, I work at a high end car stereo shop and am "that crazy project guy"

I was always planning on 24v and I did want to use the Trinamic drivers and Digikey has them for $8 so its almost a no brainer there. just glad to have conformation on that part from someone with more experience in this topic then me

One question i do have is has anyone ever used a chain drive to run multiple lead screws for the Z axis from a single stepper? This is mainly a curiosity question as I see man of the CoreXY machines with only 2 leadscrews each driven by separate motors. In my mind i see this as a point of failure due to possibility of things losing timing with each other (I also do a lot of sunroof repair and deal with issues like this constantly) For this reason the current idea in my head is 1 motor with a chain system running 2-3 lead screws for the build platform for stability. Im sure its just my mind thinking in terms outside of what I might actually encounter.Last edited by OutcastZeroOne; 05-07-2017 at 01:13 AM.

-

05-07-2017, 01:22 AM #6

There are a few different ways of setting up multiple z axis leadscrews. Two steppers working together is very reliable and does not skip steps commonly. But the Tevo black widow printer I am currently building has 2 lead screws and only 1 stepper motor. It uses a belt drive to connect the screws. It is awesome that you work in the auto industry as well. I tinker with electronics. Professionally I build AWESOME:

http://www.digitalcorvettes.com/foru...d.php?t=271354

https://www.superchargerforums.com/t...ng-a-zhz.3132/

https://www.superchargerforums.com/t...-new-ram.3141/

https://www.superchargerforums.com/t...n-lsx454.3136/

https://www.superchargerforums.com/t...own-hemi.3133/

http://www.digitalcorvettes.com/foru...d.php?t=241858

https://www.superchargerforums.com/t...n-a-7-0l.3130/

...I could wax on, but I feel it would be self serving.

-

05-07-2017, 03:34 AM #7Student

- Join Date

- May 2017

- Posts

- 16

yeah, i dont do any engine work, just audio and some interior repair like sunroofs, seats. my shop also dose convertable tops but no drive train stuff, but you know, im out in Cali

Right now im doing a $8-9k sound system in a Chevelle but yeah, fun stuff. Id post pictures but dont have many and kinda sid tracking off topic here XD

Right now im doing a $8-9k sound system in a Chevelle but yeah, fun stuff. Id post pictures but dont have many and kinda sid tracking off topic here XD

Doing some more research im finding those motors I found are a little too weak which is why they are so cheap but I found some stronger ones (39oz with 16t pullys attached) for $7 BUT only 10v coils on them so i keep digging. Im taking my time and making sure I get a good set of parts before I get anything ordered. Ive got enough useless parts laying around as it is. dont need to add to it.

This is what happens when you are the Son of a car mechanic and an electronics engineer. Dad was the mechanic, mom worked for all sorts of electronics companies, Watskin Jhonson and many others. heck, she even worked on part of the B2s original navigation system back when it was new.

-

05-07-2017, 01:01 PM #8

For strength and holding torque and the promise of no skipped steps, you will want taller stepper motors that will have multiple rows of steps for the coils to hold in place. Also the drv8825 stepper drivers are the most robust and can handle the most amperage. This is how you should be looking for strength in your stepper motors. Also 24v vs. 12v. will give you a lot more holding torque.

And of course once everything is together fine tuning your stepper drivers with a dvom and the pot on each driver will always bring you to the results you are looking for.

I don't just build engines. I take whole cars, strip them down to their last bolts and build back a whole new car, and after I'm done building, I get to tune it by way of re-writing the pcm, and then strap it down to the dyno I installed and find out what it is worth. With 15 current a.s.e. certifications, Here on the internet I am the AUTOmotive WIZzard. But in the real world during business hours, I am the corvette expert. Website:

http://www.corvette-performance-expert.com/

The dyno installation:

http://www.digitalcorvettes.com/foru...d.php?t=257986

And here are some tools I own for the auto industry that get to help me here but none of you will get the joys of experiencing:

http://www.digitalcorvettes.com/foru...d.php?t=257522

That verus edge costs as much as a new car. IT requires $1,000 updates 2x a year. And I own it personally. It is the peak of my career. I bought and traded in 4 different generations of scantools and paid heavily over the last 15 years of my career to bring me to be able to own such a tool. But just think for a minute, if you will, about the possibilities of a 4 channel lab scope tied to windows. The norm for the auto industry is 2 channels. But I can look at all 4 stepper motors on a 3d printer simultaneously and watch a printer work through its pwm commands or step counts. A resolution much of the rest of the world doesn't even know about.

At the end of the last link there is also another tool that I have that I get to use on the 3d printers. My snap-on thermal imager. How do YOU measure stepper motor temps? 1 at a time? with your finger? like mom checking her child's forehead? Or do you require precision in your knowledge like the AutoWiz?Last edited by AutoWiz; 05-07-2017 at 01:27 PM.

-

05-07-2017, 01:49 PM #9

I know I keep getting off subject here and I apologize. I get excited to talk to someone else in the biz. Just like I always did with the cars, I made build threads of building 3d printers. Not sure if this will or wont help but here is the building of my acrylic GEEEtech prusa i3 pro B:

http://www.digitalcorvettes.com/foru...d.php?t=269457

The printer I built from scratch, Printalicious, I started here:

http://www.digitalcorvettes.com/foru...d.php?t=270130

And finished here:

http://3dprintboard.com/showthread.p...Mixing-Printer

And the Tevo Black Widow I am elbow deep in building:

http://3dprintboard.com/showthread.p...-250mm-X-300mm

It is definitely better to already have a 3d printer up and running at least half way decently before you start building your own. Rapid prototyping is an invaluable asset to have when desingning and building. And your end result will definitely come out more professional than something you ground or glued or welded.Last edited by AutoWiz; 05-07-2017 at 01:56 PM.

-

05-07-2017, 02:10 PM #10Student

- Join Date

- May 2017

- Posts

- 16

yeah, and im the kind of guy who when he runs into a mess up on a personal project may start it over so that its 100% otherwise OCD kicks in and even though I may be the only one to know of the mistake, it will drive me nuts till I do something about it.

After learning a bit more about Stepper motors and their drivers, im finding that voltage ratings may not be something i need to worry about so much since a good driver will only send whats needed. At least thats what im finding, casue, you know, the internet never lies.....

so far here is what im looking at for steppers.

Z axis:

http://www.mpja.com/Stepper-Motor-NE...info/33356+MS/

X/Y axis:

http://www.mpja.com/NEMA-17-102V-Ste...info/33358+MS/

Id have to remove that 14tooth pulley and put on a 16 unless its not going to be a big deal to configure, though a larger pulley would give a little better control.

I hope to make this thing as quiet as I can so I also have to shock absorber mounts on the way. Was going to use them on my Lulzbot mini but taking a closer look there isnt enough room for them to be used without redesigning the mounts and I dont really want to do that right now The frame I will most likely make from 1" birch ply with a few car audio tricks to reduce any vibrations. Ill be testing a few ideas and will share my findings with you all if any of you would like to try some of the tricks I test out. There is also a plastic CNC guy about 1/4 mile away from my apartment that Ive known for a long time that I may have cut some parts for me too. Time will tell.

The frame I will most likely make from 1" birch ply with a few car audio tricks to reduce any vibrations. Ill be testing a few ideas and will share my findings with you all if any of you would like to try some of the tricks I test out. There is also a plastic CNC guy about 1/4 mile away from my apartment that Ive known for a long time that I may have cut some parts for me too. Time will tell.

Reply With Quote

Reply With Quote

QIDI Slicer "Plater" is...

04-12-2024, 02:21 AM in QiDi 3D Printer Forum