Results 1 to 10 of 12

Thread: Printing small objects

-

08-20-2016, 09:53 PM #1Student

- Join Date

- Aug 2016

- Posts

- 6

Printing small objects

Can anyone recommend print settings to print a small toothpick like structure on a makerbot replicator 5th gen?

In general, should slowing the printer speed down help?

Are there any tricks or tips for printing such objects?

Thanks

-

08-21-2016, 10:52 AM #2

yes slowing print speed down helps.

As does printing more than one object at a time and also get a print area cooling fan if you don't already have one.

The smaller the object - and recently I've printed objects 3mm across and 2mm high. I do know what I'm talking about - the slower you print.

Think I went down as low as 10mm/s for the really small tyres and 20mm/s for the 'big' 6mm jobs.

-

08-21-2016, 12:49 PM #3Student

- Join Date

- Aug 2016

- Posts

- 6

Thank you for verifying that.

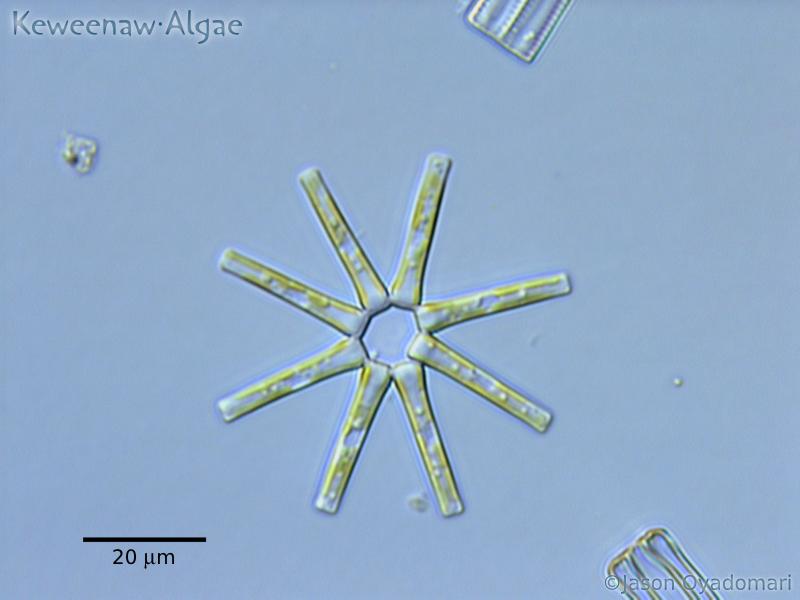

I can't seem to upload an image to the post using this browser and I don't want to post a link and get banned so if you want to get an idea of what I am trying to print you can google image search "astronella". It's the first picture and the one with the light blue background. I'm using PLA plastic and the legs often stick to the bridges when I print in different angles. (the model is 3D and not flat like those images)

As a last resort, One idea I had was to possibly print it flat, then just bend the "toothpick" arms up and down. I have managed to print very thin objects only 4 layers at .1mm by using no raft and slowing the print speeds down on the first layer. When I tried that for this 3d object.

Another question. Do thinner layers in general help when printing small objects?

-

08-21-2016, 01:13 PM #4

no not really, thinner layers just slow things down and can cause printing issues.

I found that 0.2mm is the lowest i ever need to go.

I make sling pouches (think david and goliath) that are 3x0.2mm layers, with a little squashing on the first layer they come out at around 0.5mm.

Making thinner layers would not help.

searching astronella - just get a buncjh of people and some pokemons.

do you mean this?

:origin()/pre01/f021/th/pre/i/2005/120/8/7/neopets___my_aisha_astronella_by_linnn.jpg)

lol because that really doesn't help me visualise a 3d model with toothpicks :-)

-

08-21-2016, 01:28 PM #5Student

- Join Date

- Aug 2016

- Posts

- 6

hahaha, sorry. I guess I spelt it wrong.

Try

"asterionella diatom"

That should give you plenty

I made a sling out of leather years ago. I still have it.

What kind of plastic are you using?

-

08-21-2016, 01:58 PM #6Senior Engineer

- Join Date

- Jun 2014

- Location

- Burnley, UK

- Posts

- 1,662

Aint that a starfish?

-

08-21-2016, 02:03 PM #7Student

- Join Date

- Aug 2016

- Posts

- 6

-

08-21-2016, 03:41 PM #8

As it happens my tiny wheel generator can make things like that :-)

And I did print a few that looked just like that.

So basically just print it, peel off the bed warm and while warm bend the legs to where you want them. when it cools they'll stay in place.

-

08-21-2016, 04:12 PM #9Student

- Join Date

- Aug 2016

- Posts

- 6

Yes

I'm going to try that this week when I get time with the printer. Thanks for confirming and helping me figure out some stuff. btw: I have also found it beneficial to print more than one when doing small objects. The printer needs to "warm up" before the filament comes out good it seems.

Also helps to print a couple thin small objects without rafts on opposite sides of the build plate and manually tweak the plate to get it perfectly level with the dials (if using a makerbot replicator).

-

08-22-2016, 02:27 AM #10

Printing multiple objects at once always helps.

In my experience thinner layers are only necessary to create higher surface quality where overhangs are since there will be less overhang per layer so less filament droops downward.

Printing slower and with more viscous materials such as Filaflex will help. Layfomm will also be nice for these organic models.

Ensure good bed adhesion with tape, glue/hairspray etc.

Reply With Quote

Reply With Quote

Extruder not feeding during print,...

Today, 01:59 AM in Tips, Tricks and Tech Help