Results 1 to 6 of 6

-

07-02-2016, 05:29 PM #1Student

- Join Date

- Jun 2016

- Posts

- 4

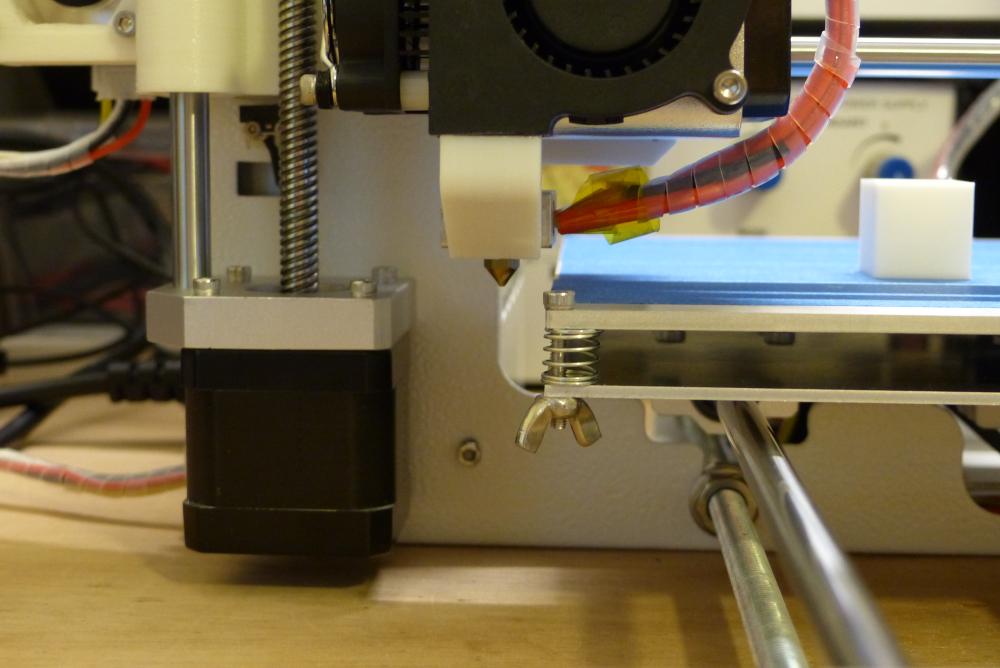

Z axis zero position -- Prusa I3 machine

I recently finished building a Prusa I3 variant, the JG Aurora A-3. Upon homing, the Z axis zero is a bit too low, about 5 mm below the bed height, even with the bed adjustments lowered about as low as they will go. There is no real way to adjust the Z limit switch position since it is screwed into threads in the metal upright. What is the best way to compensate for this? The printer is running the Marlin firmware, but I don't have the config file. I suppose I could attach a shim to the bottom of the X motor mount, which is what the Z limit switch contacts. But then what happens when I use some sort of thicker build plate in the future (e.g., glass)? Could I fix this in my start.gcode in the slicer? Thanks.

-

07-03-2016, 10:21 AM #2Student

- Join Date

- Jun 2016

- Posts

- 4

I managed to fix the problem by using shorter screws and springs for the bed height adjustment.

-

07-04-2016, 02:48 PM #3Engineer-in-Training

- Join Date

- May 2016

- Location

- SE Wisconsin

- Posts

- 206

If that design is similar to my shiny new Makerbot/Wanhao i3 then you should be able to tighten those springs down to the point that they are fully compressed. Mine came from the factory fully tightened with a fair bit of screw thread protruding out of the bottom. It certainly looks like there's a lot left in that first picture.

-

07-04-2016, 03:18 PM #4Student

- Join Date

- Jun 2016

- Posts

- 4

Thanks for your comments. Yes, you are correct, the original springs had more compression room left. However, those particular springs were so stiff that it wasn't possible to easily adjust the bed height at that point.

My long-term plan is to print an adjustable-height mounting bracket for the Z-axis limit switch. Your Wanhao limit switch height is already adjustable, correct?

-

07-04-2016, 04:10 PM #5Engineer-in-Training

- Join Date

- May 2016

- Location

- SE Wisconsin

- Posts

- 206

I know what you mean. On one of the thumbwheels, it bound up slightly while turning and was pretty difficult to turn through about 100 degrees of it's rotation.

And I just checked, turns out I have about a quarter inch of adjustment on that limit switch, yes. perhaps you could modify the design a little to include slots?

or perhaps print a bracket that adds the ability to adjust it to your unmodified mounting holes?

Now that I actually have this thing, and am thus far having good luck with printing, I am pretty excited to get to designing stuff.

-

07-07-2016, 01:56 PM #6Engineer-in-Training

- Join Date

- Jul 2016

- Location

- Pennsylvania, USA

- Posts

- 255

Hi

You need to get to a design for the end stop that can accommodate the entire range of the adjustments on the bed height. This is normally done by a printed part with a captive nut and bolt to make the adjustment.

Bob

Reply With Quote

Reply With Quote

QIDI Slicer "Plater" is...

04-12-2024, 02:21 AM in QiDi 3D Printer Forum