Results 3,401 to 3,410 of 4110

Thread: Qidi Tech 1 - Replicator 1 clone

-

09-29-2016, 09:02 PM #3401Technician

- Join Date

- Sep 2016

- Posts

- 80

OK. So.

I had my clogged arm - it's the plastic piece with the hole at the top that has the lever at the end. Qidi is sending me a replacement - presumably just for that piece. So, since I had a replacement on the way I decided to really put some effort into it, got a bigger drill bit, and opened up the hole. The problem was, basically, I had a C-shaped piece still in there, and it didn't leave enough room for a piece of 1.75mm filament to go through.

I reassembled, did a filament load, and filament flowed normally.

Then I tried to print, and ended up with a mess. A little getting laid down, and a lot getting dragged all over the place. Re-leveled. Tried again. Same thing.

I did that a few times, all spectacular failures.

Then I did a print from the left printhead. And it's looking pretty close to perfect.

So, any thoughts on what I could have wrong with the right printhead? I can't have it mis-leveled or anything. At least I can't see HOW I could manage that.

-

09-29-2016, 09:28 PM #3402Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

Using the filament load function, does the problem right printhead seem to extrude normally? Any clicking sounds? Temperature numbers OK? Typically the R and L nozzles are at SLIGHTLY different elevations, so that might be an issue. Do R and L have the same material loaded? Are the settings the same in S3D or whatever slicer you are using?

-

09-29-2016, 09:32 PM #3403Engineer

- Join Date

- May 2016

- Location

- Annapolis, MD

- Posts

- 523

-

09-29-2016, 10:34 PM #3404

-

09-30-2016, 12:06 AM #3405Technician

- Join Date

- Sep 2016

- Posts

- 80

Seems to extrude normally. Definitely no clicking sounds. Temperatures look good. They don't have exactly the same material (both Hatchbox PLA, different colors), but close. I'm using S3D, and I'm doing same settings, apart from swapping nozzles.

-

09-30-2016, 05:49 AM #3406Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-30-2016, 05:51 AM #3407Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-30-2016, 05:54 AM #3408Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

-

09-30-2016, 06:39 AM #3409

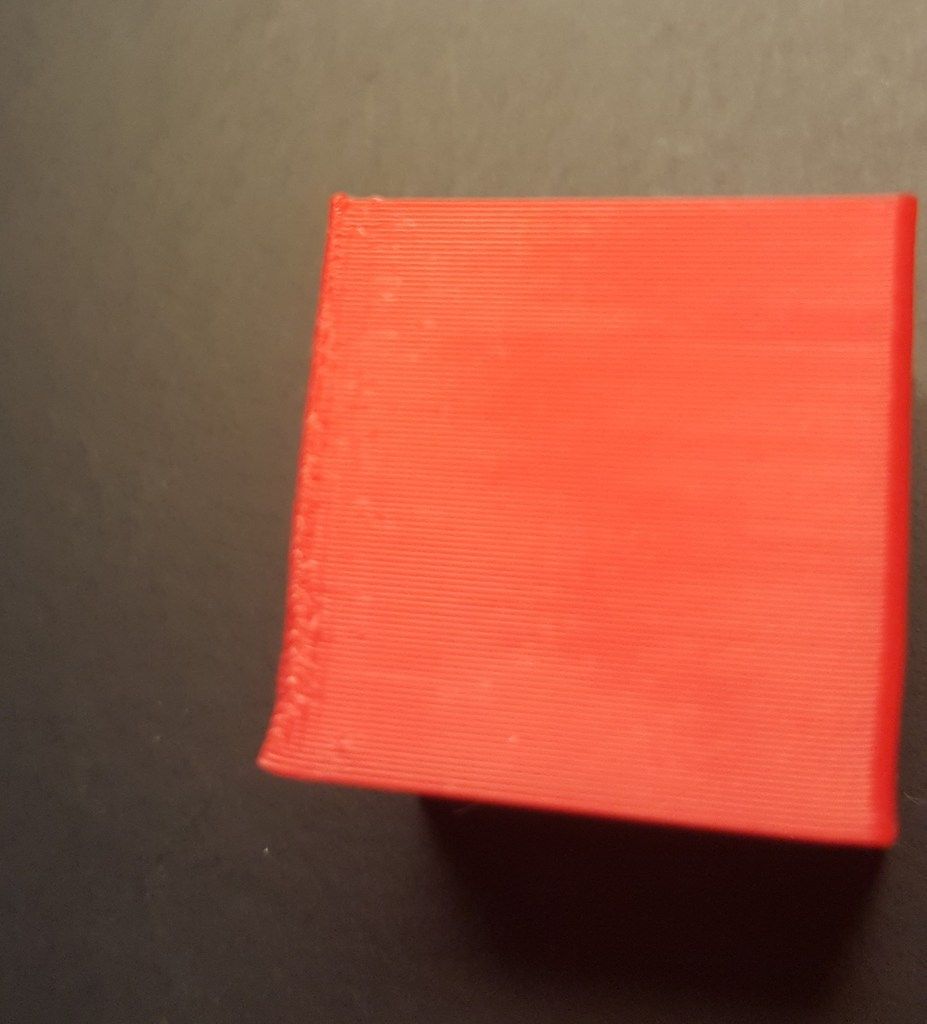

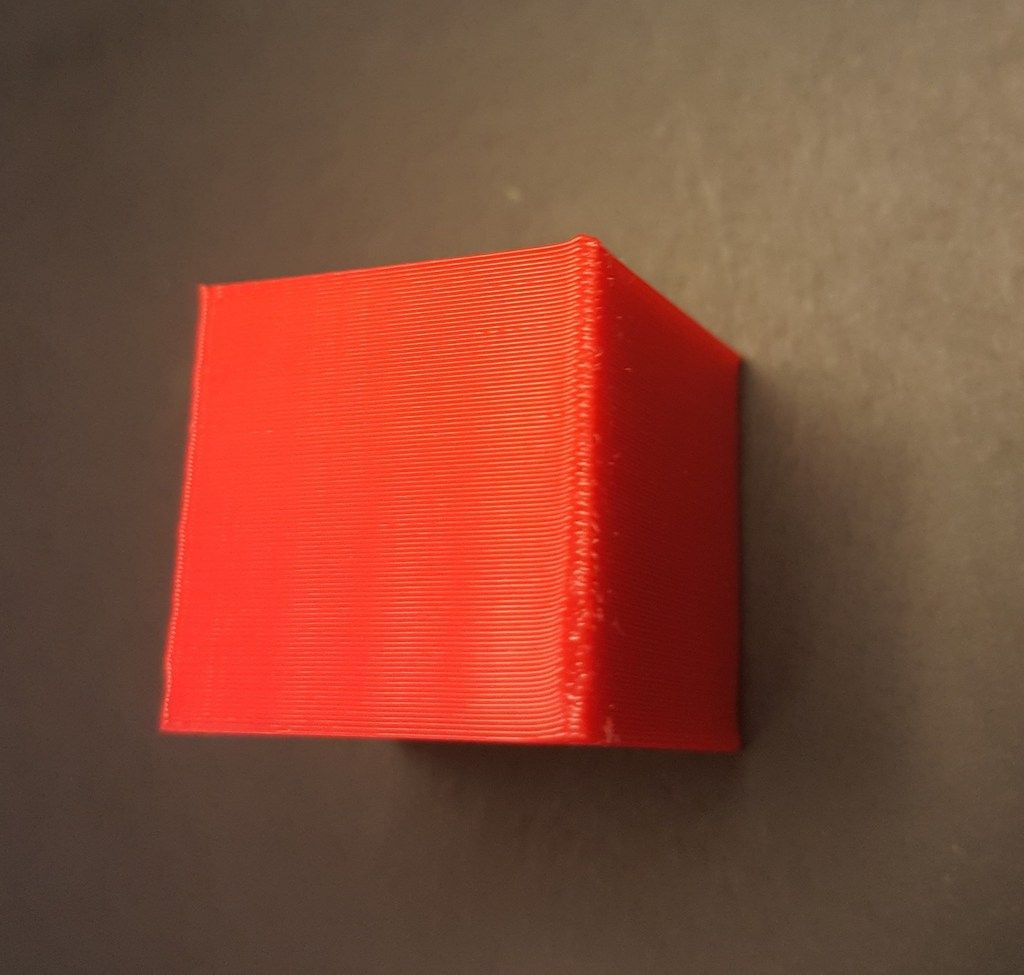

What does the top of that cube look like? Is it 100% infill? Why is it so tall? A calibration cube is supposed to be 20x20x10. It is helpful to note which axis is which.

Temp is about 20c too low for ABS. Bed is about right. May need to use slurry to keep it stuck.

-

09-30-2016, 07:20 AM #3410Super Moderator

- Join Date

- Jun 2016

- Location

- Oklahoma

- Posts

- 904

The top is ok but it is not at 100% yet. It is a 20X20X20, I keep forgetting to cut it down! Orientation would be as I am facing the printer this deformed area is the right rear corner.

At first I thought it was because I had selected specific start point for the extruder but when I re-ran it with optimized selected it still did it but not as bad however then I get the saw-tooth effect on the corners of the cube! Another issue to deal with.

I switched back to a Makergeeks white ABS last night and am running the cube again and I think I am not getting this issue. I will be able to start testing later.

Reply With Quote

Reply With Quote

QIDI Slicer "Plater" is...

04-12-2024, 02:21 AM in QiDi 3D Printer Forum